2D ENGINE

Engineering new 2D materials phases not existing in nature

2D ENGINE

Engineering new 2D materials phases not existing in nature

Project Coordinator

Thanasis Dimoulas, National Centre for Scientific Research DEMOKRITOS, Greece

Imagine materials as thin as a single atom, yet possessing incredible strength, flexibility and electrical properties. These are not the stuff of science fiction, but the result of cutting-edge engineering. Two-dimensional materials (2DM), best exemplified by graphene — a single layer of carbon atoms arranged in a honeycomb lattice — have opened the door to a universe of possibilities that were previously unimaginable.

In this project we are pushing the boundaries even further by engineering new phases of 2DM which cannot be produced in bulk form by equilibrium growth methods, so they cannot be exfoliated but they can only be engineered as atomically thin 2D films by synthetic methods. Essentially, we will be creating materials with tailored properties for specific applications. These materials could revolutionise industries, such as electronics, where they could lead to the development of ultra-fast, ultra-thin and energy-efficient devices.

We target a class of materials that are semiconductors (GaN, SiC) and insulators (AlN) adopting the wurtzite 3D structure in their bulk form. These materials are polar, accumulating charge and building electrostatic energy on their surface. Under a critical thickness of a few monolayers, the materials transition to a flat, non-polar 2D hexagonal phase resembling that of hexagonal boron nitride (hBN) in order to minimise or eliminate the electrostatic energy. The main objective is to engineer these materials in the targeted 2D hexagonal phase and incorporate them into proof-of-concept transistors, memory and light emitting diode devices, to show that they can have an impact on electronic and photonic technologies.

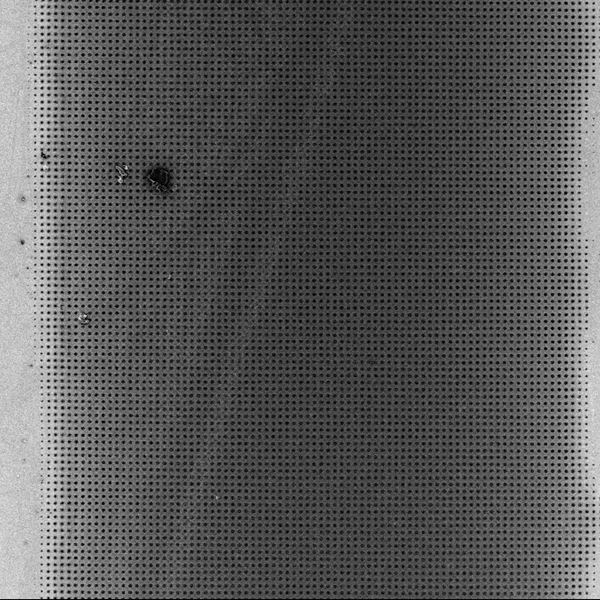

Key enablers are the liquid metal catalyst technology for the seamless growth of large-area single-crystal 2D layers and radiation-mode optical microscopy for real-time monitoring of growth. Our methodology will be further supported by atomistic simulations, molecular beam epitaxy growth and several in situ and ex situ surface analytical techniques to validate the new 2D hexagonal phases. We will leverage previous results published by consortium members on the liquid metal catalyst growth of graphene and the molecular beam epitaxy growth of hexagonal AlN on silver, to extend these methodologies to the new materials phases targeted in this project.

Meeting new challenges

2D ENGINE is expected to impact electronics and photonics and primarily aims to provide solutions for the miniaturisation of mainstream transistors beyond the 2nm technology node. Our materials could help bringing Moore’s law to the angstrom regime. Moreover, 2D light-emitting diodes efficiently coupled to planar waveguides could be ideal for the realisation of photonic integrated circuits for on-chip optical communication. It proposes a totally new materials class beyond graphene and 2D transition metal dichalcogenides which have been intensely investigated. The 2D ENGINE materials are 2D semiconductors and insulators with sp2 hybridisation offering stability that rivals that of graphene but additionally possess an electronic band gap that makes them better suited to efficient transistors for digital logic and for light emission and optical information processing.

The proposed new 2DM phases are expected to inherit some of the desired properties of their well-known parent 3D materials (SiC, GaN, AlN), including their processability and compatibility with Si processing. One of the biggest challenges is finding suitable atomically thin and stable 2D semiconductors which will allow the ultimate scaling of the active channel thickness to the angstrom regime. Thin channels allow for better electrostatic control so devices could be laterally scaled to the nanometre range without suffering from short channel effects. In the end, this will allow the miniaturisation of devices for the benefit of reduced cost, combined with higher performance and lower static and dynamic power dissipation. While 2D semiconductors from the transition metal dichalcogenides family do exist, these are not so stable, especially after transferring to target substrates, while optimum contacts and doping have not been identified. The 2D ENGINE semiconductors could help overcome the shortcomings of present 2D semiconductors, providing more stable materials with better processability.

Sustainable solutions

2D ENGINE, through the miniaturisation of mainstream digital electronic and photonic devices, will ensure low cost, high density and low power consumption to face the challenges of handling a large amount of inhomogeneous and unstructured information in the Cloud and at the edge, leading to a sustainable Industry 4.0 evolution. Moreover, device miniaturisation and optical on-chip communications could lead to energy-efficient integrated circuits with an immediate impact on energy savings and the environment.

New horizons

In the first year, 2D ENGINE will focus on the growth and validation of 2D phases to make sure that the hexagonal 2D phase is obtained, as targeted. Then, the consortium will evaluate the stability of the materials in order to prepare for the device fabrication planned within the first 36 months of the project. To achieve our most urgent objectives in the first 18 months, the main challenges faced are associated with the growth of ultrathin layers below the critical thickness to induce the transition to the 2D hexagonal phase. An important, related issue is to obtain large-area crystals in the mm scale, to facilitate device fabrication. To face these challenges, two different growth methodologies, namely liquid metal catalysis and molecular beam epitaxy will be employed to maximise our chances of success. An equally important challenge is to confirm the 2D hexagonal phase of the grown thin films. To achieve this, several in situ and ex situ surface analytical techniques will be employed, including high-resolution and high-sensitivity synchrotron X-ray scattering, complemented by atomistic modelling.

Collaborations

Collaboration with other projects in the electronics and photonic clusters of the Graphene Flagship ecosystem is expected to benefit 2D ENGINE, although these projects have higher technology readiness level (TRL). Interaction with the active 2D-EPL and the possible successor project is expected to promote our goals. We envisage valorising our liquid metal catalyst technology by investigating the compatibility with established 2DM processing practices in a 2D pilot line. Integration of inspection tools developed in 2D ENGINE with the pilot line and investigation of cross-contamination issues will be a priority in our interaction with the 2D-EPL. Depending on the 2D ENGINE results, an MPW run at the 2D pilot line of a photonic integrated circuit based on a 2D light emitting diode integrated with a waveguide is planned at the end of the four-year project. Our long-term vision is that 2D ENGINE catalyses the interaction between the Graphene Flagship community and the broader Chips Act initiative in Europe and the Chips Joint Undertaking in specific. The 2D ENGINE goals match well with the Chips JU pilot lines and competence centre plans. More specifically, the plans of 2D ENGINE regarding a photonic integrated circuit based on 2D SiC or GaN could take advantage of optically addressable spin defects (known in bulk SiC as colour centres/single photon emitters) to create a spin-photon interface for qubit and quantum entanglement targeting quantum communications. Such an activity could contribute to the effort for quantum chips within the Chips JU initiative making the 2DM community a key player in the Chips Act European endeavour.

Partners

National Centre for Scientific Research DEMOKRITOS, Greece

European Synchrotron Radiation Facility, France

University of Patras, Greece

Leiden University, Netherlands

Leiden Probe Microscopy, Netherlands

AMO GmbH, Germany

Max-Planck Society for the Advancement of Science, Germany

Related articles

Exploring the interaction of 2D materials and biological systems with Valentina Castagnola

The IIT researcher focuses on the interface between the bio and nano realms

Making structures on 2D materials with a 3D printer

A new method for creating nanopatterns on layered materials