Materials of the future: Graphene and lignin

“Lignography”: the art of making sensors out of wood scraps

The use of wood in construction has resurfaced due to growing concerns over the environmental impact of concrete. However, wood absorbs moisture from its surroundings, leading to rotting, mold, and other kinds of damage. In Sweden alone, the cost for repairing water damages in buildings exceeds 500,000,000 euros per year. To address this issue, researchers of the Graphene Flagship Associated Member Research Institutes of Sweden (RISE) have developed a graphene sensor embedded in wood that can detect both ambient humidity and moisture inside the wood.

RISE coordinates the Digital Cellulose Center (DCC), which aims to make forest-based materials and products part of the digital world, via sustainable electronics and the circular economy. “The graphene humidity and moisture sensor has really demonstrated a sustainable way for electronics and has raised a high interest from both DCC’s academic and industrial partners,” says DCC Center director Ursula Hass, who is based in RISE.

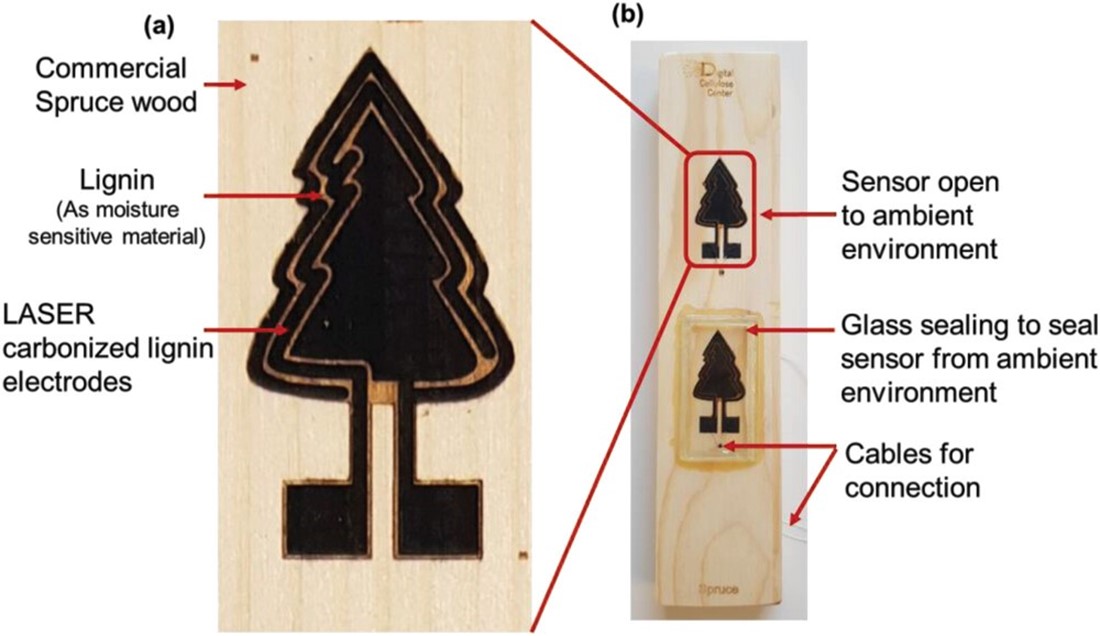

In this “Lignography” method, the team patterned sensors using a printable ink composed of lignin – a complex organic polymer found in the cell walls of many plants and a byproduct of the paper and pulp industry – and cellulose, which were converted into graphite or graphene upon irradiation with a laser beam.

Following the graphitization process, these sensors were able to measure humidity levels in a range from 10% to 90% at 25°C in different types of wood. The sensors fabricated on spruce and pine wood exhibited high sensitivity, with values of 2.6 and 0.74 MΩ for every 1% increase in humidity, respectively. Finally, the researchers showed that the changes in humidity collected by these sensors can be remotely read through a connected computer or visualized with a simple LED system.

Humidity sensor manufactured on commercially available spruce wood. a) The wood was first coated with a water-based ink containing lignin and cellulose polymers in the shape of a spruce tree. A CO2 laser was subsequently used to produce two carbon electrodes from the ink coating, while leaving some ink untouched between the electrodes to work as an adsorption layer for moisture sensing. b) Two sensors fabricated on a wood surface, one sealed from front side, while the other was kept open to ambient environment. (Credit: RISE)

RISE researchers have also demonstrated lignin graphitized electronic components, such as resistors and triboelectric energy harvesters, involving similar “lignography” processes.

“The research from our group paves the way for the development of bio-graphene based sensors, energy harvesters, and electronic devices and circuits based on sustainable and recyclable materials, such as wood and paper. By utilizing these materials that can be discarded in paper bins, we hope to eliminate the need for electronic bins,” explains Mohammad Yusuf Mulla from RISE.

Beyond humidity sensors on wood, RISE researchers in collaboration with Lignin Industries AB and Bloom Renewables SA are also working on new types of lignin-based materials that can detect pressure and mechanical inputs. For example, these ‘smart materials’ can be used to operate on/off switches and volume controls via bending or tapping instead of pressing buttons.

The team prepares the smart lignin-based materials by chemically modifying lignin into either thermoset or thermoplastic formulations. Functional additives such as BaTiO3 and reduced graphene oxide are added to these composites. When an external force is applied to a BaTiO3 crystal, the crystal structure is distorted, causing its positive and negative charges to separate and resulting in the generation of an electric field. At the same time, graphene – an excellent conductor of electricity – boosts the conductivity of lignin-based composites allowing for the efficient transfer of electrical charges. Compared to lead-based commercial piezoelectric materials, lignin-based materials are safer and more sustainable additive for touch and pressure sensors.

“Thanks to novel materials like graphene, we envision a future generation of materials that could be extracted from wood instead of petroleum and do interesting things with a tap of our fingers,” says Abhilash Sugunan from RISE.

References

Mulla, Mohammad Yusuf, et al. "Bio-Graphene Sensors for Monitoring Moisture Levels in Wood and Ambient Environment." Global Challenges (2023): 2200235. https://onlinelibrary.wiley.com/doi/full/10.1002/gch2.202200235

Edberg, Jesper, et al. "A Forest‐Based Triboelectric Energy Harvester." Global Challenges 6.10 (2022): 2200058. https://doi.org/10.1002/gch2.202200058

Edberg, Jesper, et al. "Laser-induced graphitization of a forest-based ink for use in flexible and printed electronics." npj Flexible Electronics 4.1 (2020): 17. https://www.nature.com/articles/s41528-020-0080-2

Digital Cellulose Center (DCC), https://digitalcellulosecenter.se/