Graphene 101: All about graphene and its many forms

Welcome to the world of graphene. On these pages, learn about the different forms of graphene, how they are made, and what they can do.

The Graphene Flagship is racing to find the most efficient and effective ways to make graphene and its derivatives, as well as to establish new standards and lead the way to commercialisation. In fact, graphene’s market penetration is on the rise, with a projected year-on-year growth rate of 40% by 2025.

Graphene: conductive, flexible and strong

Graphene is a one-atom-thick sheet of bonded carbon atoms with a hexagonal structure, like chicken wire. Even when it is not one-atom-thick, the material still retains some of the unique properties of the single-layer form. This is called multi-layer graphene, and it has similar properties to graphene up to a thickness of about 10 layers.

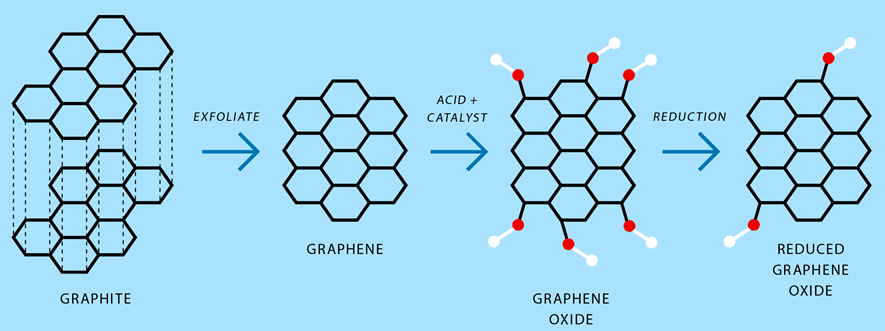

One way to make graphene is to break down natural or artificial graphite, which consists of stacked graphene layers bonded weakly by van der Waals forces. Graphene’s properties far exceed those of its mother material, graphite. Just as you have no doubt experienced when writing with a pencil, graphite is naturally brittle – and yet graphene is one of the strongest materials in the world. It is also transparent, elastic and flexible.

Single-layer graphene is used for high-end technical applications like supercapacitors, solar cells and semiconductors. Multi-layer graphene is used in applications like composites, where the need for a carefully tailored electronic structure is less important. Products containing single-layer and multi-layer graphene have been released to the market in several forms, including powders, solutions, inks and pastes. Functionalised graphene could even remove heavy metal pollutants from water.

Graphene can be produced using mechanical, thermal or liquid-phase exfoliation - the act of ripping layers off the bulk material. Liquid phase exfoliation just celebrated its 10th anniversary! Alternatively, graphene can be deposited onto a substrate from a carbon-rich source, such as methane, using a method called chemical vapour deposition (CVD). This can produce high-quality single-layer versions of graphene, suitable for high-performance applications in photonics, sensing and wafer-scale electronics.

Graphene oxide: the water-loving graphene

Graphene oxide is made by treating graphite with strong oxidisers like sulphuric acid, alongside a catalyst like potassium permanganate and sodium nitrate. These procedures add oxygen atoms to its surface and make the material hydrophilic, meaning it can be dispersed in water. Plus, depending on the ratio between the number of carbon and oxygen atoms, graphene oxide films can either be a conducting or insulating material.

Graphene oxide is important for a broad range of applications like biomedicine, fire protection, energy storage and composites. It is also used to make transparent films for flexible electronics, solar cells and chemical sensors such as drug tests.

We can even build 3D structures out of graphene and graphene oxide flakes, like aerogels for conductive inks or a chrysalis that makes magnesium batteries more sustainable.

Reduced graphene oxide: the economically valuable graphene

Scientists can reduce graphene oxide to make a different, economically valuable material. Although reduction does not remove all oxygen groups from the material’s surface, it does partially restore graphene’s electron transfer properties. Laser-scribing, chemical, thermal or electrochemical reduction are all viable techniques for converting graphene oxide into reduced graphene oxide.

Reduced graphene oxide can also be functionalised to endow it with new properties suitable for a variety of commercial applications, such as electrochemical sensing.

The validation service: quality control

If a material is to have applications in industry, its quality and composition need to be reliable and reproducible, and it must be made from consistent source materials. To help with these needs, the Graphene Flagship Validation Service offers a set of tests including structural, mechanical, optical, thermal, electrical, magnetic, chemical and lifecycle measurements to assess and validate the performance of graphene-based devices and materials.

Clients of the Validation Service receive a detailed report from authorised institutions: Graphene Flagship partners the National Physical Laboratory in the UK, the University of Zaragoza in Spain and LNE in France.

https://suppliers.siografen.se/

https://suppliers.siografen.se/