Graphene applications: G+BOARD

Graphene Flagship Spearhead Project G+BOARD aims to create the dashboard of the future. Unlike existing vehicle dashboards, many of which use metal, the inclusion of graphene-based materials in the vehicle dashboard can significantly reduce the weight of the vehicle.

G+BOARD is a project to develop an innovative metal-free car dashboard, that replaces the copper wiring and other discrete functional elements with new GRM-based materials with integrated properties.

The dashboard’s new features are integrated by etching a thermoplastic composite polymer with a laser. Where the laser strikes the thermoplastic polymer, many complex physical and chemical processes occur, resulting in the insulating plastic being ‘patterned’ with conductive graphene. This results in a more aesthetic, compact, and durable dashboard, designed to reduce production costs for manufacturers and decrease fuel consumption for end users.

Thanks to graphene’s electronic properties, only a very small quantity needs to be added in order to create the conductive pattern. Using such small quantities makes the processing steps more straightforward, requiring less energy and fewer resources, and leaves the dashboard’s structural and mechanical properties unchanged.

Devices and sensors are connected to the dashboard through these conductive patterns, eliminating the need for copper wiring and mechanical buttons that most dashboards use today.

G+BOARD is lighter than other car dashboards. This benefit is passed straight on to the driver, as a lighter vehicle means less fuel consumption. The graphene-based wiring alternative can also be applied to other features and installations, such as door panels, switches, and computer consoles.

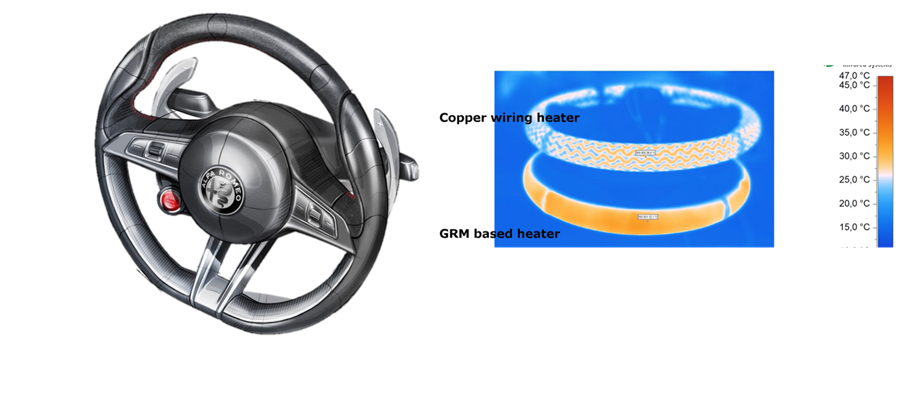

Additionally, the GRM-based materials can also replace traditional heating systems with innovative copper-free heating elements. G+BOARD avoids the requirement for a copper element inside heated steering wheels, providing faster, more uniform heating. The graphene-based heating system can also be adapted for heated seats and gear knobs.

Manufacturing G+BOARD is more sustainable than traditional dashboards, as it avoids the need for copper entirely, and requires only a very small amount of graphene per dashboard.

Furthermore, G+BOARD requires fewer steps to fabricate, meaning less energy is needed on the production line, helping to make our automotive industry greener and more sustainable – and it is easier to recycle, to boot.

Manufacturing G+BOARD is more sustainable than traditional dashboards, as it avoids the need for copper entirely, and requires only a very small amount of graphene per dashboard.

GRM-based materials can replace traditional heating systems with innovative copper-free heating elements. G+BOARD avoids the requirement for a copper element inside heated steering wheels, providing faster, more uniform heating.