Layered materials for energy generation and heat pumps

A conversation with graphene researcher Ilaria Pallecchi, coordinator of the Graphene Flagship Partnering Project MELoDICA. Transition metal dichalcogenides (TMDs) are layered materials that offer alternative benefits in many different applications. A good example is thermoelectricity: the direct and reversible conversion of heat into electricity.

The Graphene Flagship Partnering Project MELoDICA was selected in the FLAG-ERA Joint Transnational Call 2017 to investigate the thermoelectrical properties of TMDs. Completed in October 2021, the project was coordinated by Ilaria Pallecchi, of Graphene Flagship Partner Consiglio Nazionale delle Ricerche (CNR, Italy), in collaboration with researchers of former Graphene Flagship Associated Members University of Liege (Belgium), the Institute of Nanoscience and Nanotechnology, NCSR-Demokritos, (Greece) and Babes-Bolyai University (Romania).

In this interview, we ask MELoDICA’s coordinator Ilaria Pallecchi about her experience with thermoelectricity studies and the project’s accomplishments.

Why are you interested in the thermoelectric behaviour of TMDs?

The electronic structure of bulk TMDs is different from that of few monolayers, therefore these materials offer a wide possibility of tuning electric and thermoelectric properties. Their thermoelectric behaviour has not been as widely investigated.

Which types of applications of thermoelectric materials can you foresee?

If waste heat is used to produce electricity, thermoelectricity represents a green path to energy harvesting. Conversely, thermoelectric materials can also be used as pumps that use electrical energy to either heat or cool devices. Both energy harvesting and heat pumping applications are relevant in large-scale as well as micrometre-scale applications. In the latter case, thermoelectrics can be employed to feed power from waste heat to electronic devices and in the thermal management of electronic circuits, like micrometer-scale cryo-coolers.

How do you measure thermoelectricity?

Thermoelectric properties are measured by feeding heat into one side of a suspended sample, under vacuum, while the other side is kept at a fixed temperature by a heat sink. This way, a thermal gradient is established, which makes electrical charges diffuse from the hot to the cold side. In steady-state conditions, a voltage drop develops to counterbalance the carrier diffusion. The simultaneous measurement of voltage drop and temperature drop allows us to extract the Seebeck coefficient.

Which high-performance TMDs did you focus on?

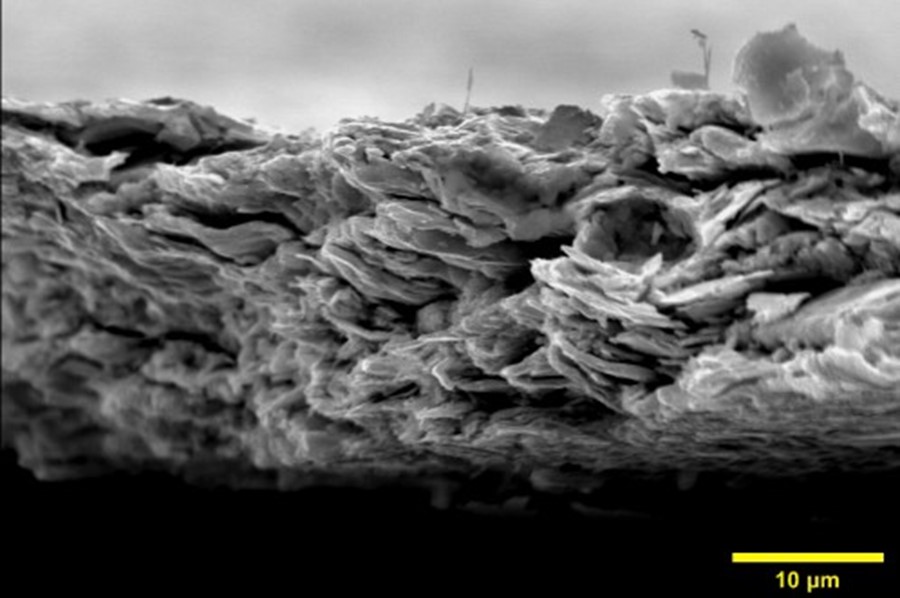

We studied several sulfide, telluride and selenide compositions in the form of mechanically exfoliated single-crystalline flakes. We choose diselenide (SnSe2) and tungsten diselenide (WSe2) for the preparation of assemblies as suggested by our theoretician partners. These have prospects for use in thin-film thermoelectric devices for cooling electronic components and generating micro-scale electricity. We purchased WSe2- and SnSe2-based inks from Graphene Flagship Partner BeDimensional SpA in Italy and dissolved them in ethanol because of its low toxicity and low boiling temperature. Starting from these inks, we devised a protocol for the fabrication of TMD assemblies, obtained by liquid-phase exfoliation. We deposited them by ink-jet printing and drop-casting on different substrates, such as mica, quartz and flexible Kapton.

Can TMDs perform better than bismuth telluride, one of the most popular thermoelectric materials?

TMDs in the form of mechanically exfoliated single crystalline flakes and films have thermoelectric power factors – the product of squared Seebeck coefficient and electrical conductivity – comparable to commercial thermoelectrics, such as lead telluride and bismuth telluride.

The electronic transport in inkjet printed and drop-cast assemblies is limited by grain boundaries. The application of these fabrication techniques to TMDs is pioneering, high risk/high gain. Obtaining any electrical conductivity at all was in itself a remarkable success.

This is an encouraging starting point, considering that there exists plenty of possibilities to manipulate electronic and heat transport and improve thermoelectric performances of TMDs. We can exploit their composition, use different phases, prepare composite materials, intercalate other elements, or optimize electronic parameters by field effect. Furthermore, the layered nature of TMDs is also an added value, as flakes can be transferred on flexible substrates, such as Kapton.

Which are the challenges of producing thermoelectric materials?

Thermoelectric properties are commonly assessed by the figure of merit ZT, which represents the conversion efficiency between heat and electricity. To obtain the largest ZT values, thus best performance, thermoelectric materials should have a large Seebeck coefficient, large electrical conductivity, and very low thermal conductivity. The optimization of ZT is a moonshot challenge of material science, in that Seebeck coefficient and electrical conductivity usually have opposite trends, so that they cannot be simultaneously increased. On the other hand, many efforts focus on reducing thermal conductivity. We changed nanostructural features to tune electrical and thermal transport almost independently, in such a way that irreversible heat transport is minimized, while simultaneously maintaining good electrical properties.

What have MELoDICA’s greatest achievements been?

We combined theoretical and experimental approaches to identify TMD compositions promising for thermoelectric applications. Athanasios Dimoulas from NCSR-Demokritos and I worked with our theoretical partners, Daniel Ioan Bilc from Babes-Bolyai University and Matthieu Verstraete from University of Liège. We developed a statistical model to estimate electrical, thermal and thermoelectric properties of TMD assemblies, which correlates electrical and thermal properties with the nature of the interfaces at a microstructural scale. This model can be used to optimize electrical, thermal and thermoelectric properties of other materials, used in several industrial applications.

References

- Patil, B., et al. "Ink-jet printing and drop-casting deposition of 2H-phase SnSe2 and WSe2 nanoflake assemblies for thermoelectric applications." Nanotechnology 33.3 (2021): 035302.

- Pallecchi, I., et al. "Review on thermoelectric properties of transition metal dichalcogenides." Nano Futures 4.3 (2020): 032008.

- Xiao, Peng, et al. "Anisotropic Thermal Conductivity of Crystalline Layered SnSe2." Nano Letters (2021).

- Bilc, Daniel I., et al. "Electronic and Thermoelectric Properties of Transition-Metal Dichalcogenides." The Journal of Physical Chemistry C (2021).

- In addition, here's a full list of publications of the MELODICA project.

Cross-sectional SEM images showing a section of SnSe2 assemblies on Kapton, obtained by liquid phase exfoliation and drop casting (Photo credit: Ilaria Pallecchi).

WSe2 ink and ink-jet printing of WSe2 flakes on photographic paper, reproducing the project acronym MELoDICA as pattern (Photo credit: Ilaria Pallecchi).