‘Mille-feuille’ pastry inspires graphene pressure sensor

The Graphene Flagship launched on 1st October 2013. Six years later, researchers from Graphene Flagship partner Université de Strasbourg, France, developed a graphene-enabled pressure sensor inspired by French famous multi-layered pastry - the 'mille-feuille'.

Graphene Flagship scientists at Université de Strasbourg and CNRS, France, together with researchers at Adam Mickiewicz University, Poland, and University of Florence, Italy, developed a wearable, highly sensitive graphene pressure sensor capable of picking up even a faint heartbeat while worn on the skin.

Inspired by layered French pastries, 'mille-feuilles', researchers built a sensor that can be understood in terms of simple high school science. Paolo Samorì, researcher at Graphene Flagship partner Université de Strasbourg and CNRS, France, explains: "We all studied Hooke's Law during high school; it tells us the relationship between the force on a spring and its compressibility, defined by the spring constant. So, our idea was to prove that, on the nanoscale, you can learn from Hooke's Law to develop highly sensitive pressure sensors."

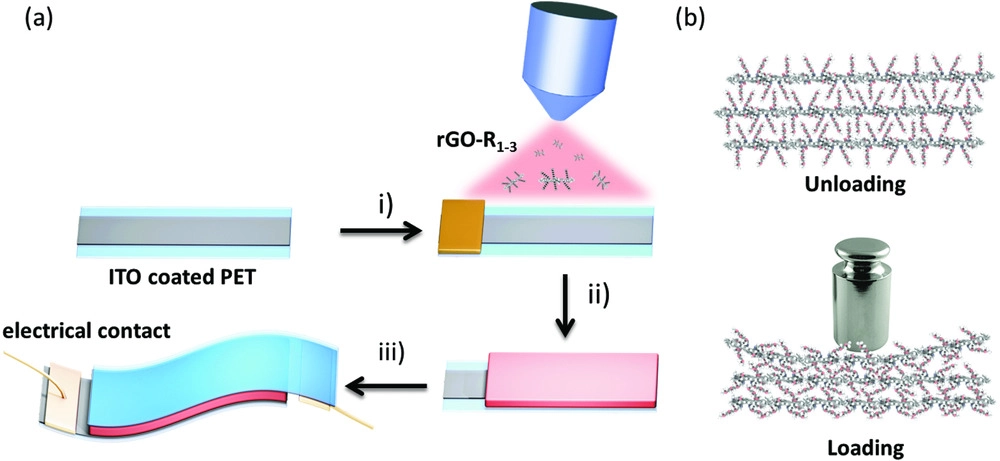

But what could be used as a spring on such a small scale? "Molecules!" answers Samorì. "Molecules can be seen as tiny springs." Researchers replaced puff pastry and cream with layers of molecular springs and graphene oxide. In this molecular sandwich, alternating layers are covalently linked, and electrodes are then attached to the top and bottom graphene layers. "When you apply pressure to the top of the structure, you compress the springs – and how much the springs compress will depend on the spring constant," continues Samorì. Different molecules exhibit different spring constants, and a greater compressibility makes for a more sensitive device. Thus, spring molecules can be carefully baked into the mix to tune the pressure sensitivity for each purpose.

The design works thanks to the high electrical conductivity of graphene. Pressure applied to the top of the mille-feuille structure compresses the springs and pushes the graphene layers closer together. This increases the probability of charge tunnelling from one layer to the next, which means that a greater conductivity results in better electrical performance of the device.

© 2018 WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim

The Graphene Flagship team in Strasbourg used the device as an on-skin pressure sensor to monitor patients' heartbeats. This was only possible thanks to the high sensitivity and compressibility of the graphene 'mille-feuille' sensor. "Moreover, this device operates with a very, very low voltage, about 0.2 V, thus it does not need a very heavy battery to be powered," added Samorì.

Artur Ciesielski, Graphene Flagship researcher and co-author, believes the sensor's properties give it potential to be used as a portable and wearable health and fitness tracker. "Potential applications go far beyond health monitoring – this is just a small portion of the pressure sensing devices that are essential to everyday life," he says. "Large sensors could be fabricated by spray painting mille-feuille-like graphene ink onto a surface. I wouldn't be surprised if, in the near future, this approach could be used to make smart buildings – where the flooring can be coated with our mille-feuille structures, in order to monitor human movement, leading to ultrasensitive solutions for home security."

Maria Smolander, Graphene Flagship Flexible Electronics Work Package Leader, is optimistic about this development: "This highly sensitive pressure sensor developed by Samori's group is indeed very interesting and an important concept. In the Flexible Electronics Work Package of the Graphene Flagship, partners are currently implementing this sensor to wearable autonomous sensing devices for health monitoring, together with other flexible electronic developments."

It is still early days for the 'mille-feuille' sensor to be commercially available, but Samorì believes that products based on this technology could reach the market in the next five years. "We are working with commercial companies to bring this product to the factory floor, but I can't say too much more about them at this stage."

Andrea C. Ferrari, Science and Technology Officer of the Graphene Flagship and Chair of its Management Panel, adds: "Sensors are a key application area for graphene and related materials. This work opens new opportunities for health monitoring and shows the steady progress of the Flagship to realize innovative devices."

Reference

'Molecule–Graphene Hybrid Materials with Tunable Mechanoresponse: Highly Sensitive Pressure Sensors for Health Monitoring', Advanced Materials, 2019, 31, 1. Chang-Bo Huang, Samanta Witomska, Alessandro Aliprandi, Marc-Antoine Stoeckel, Massimo Bonini, Artur Ciesielski, and Paolo Samorì.