Spotlight: Lucia Lombardi

The Graphene Flagship's Spotlight explores the experience of the researchers behind the results. Lucia Lombardi has been involved in many different projects during her PhD. She spoke to the Graphene Flagship about how she balances her research.

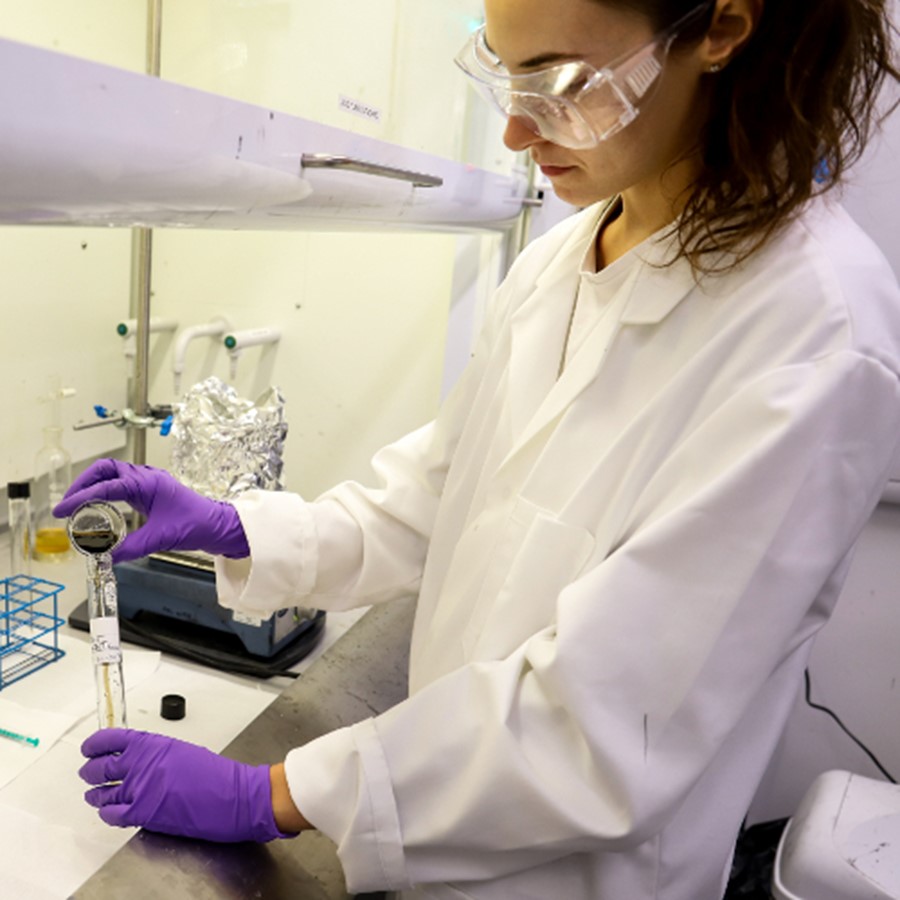

Lucia Lombardi is a PhD student working with Andrea Ferrari in the Cambridge Graphene Centre at the University of Cambridge, UK. Lucia has worked on a variety of different projects, using liquid-phase exfoliated graphene and related materials for different applications. Lucia is involved in the Zero Gravity Graphene experiment for improving loop heat pipes for cooling in satellites by coating the wicks with graphene. Taking a break from writing her thesis, she told the Graphene Flagship about her experiences working in the lab.

How did you get involved in graphene research?

I studied in Materials Engineering and Nanotechnology for my Bachelors' and Masters' degrees in Milan. I was lucky to finish early, and my supervisor told me there was a good professor studying new materials that are really promising from an electronic point of view, but also good for making composites and other applications. I agreed with Andrea to come to Cambridge for six months to do a thesis project, and I worked on the exfoliation of other layered materials. After the thesis, Andrea offered me a PhD that was a bit different – printed electronics with other layered materials. The main idea was to make transistors, fully printed, with decent mobility and on-off ratio.

As well as the printed electronics, you've been involved in several other projects during you PhD. What else have you worked on?

In the four years of the PhD, I have realised that making printed electronics with layered materials is not that easy, even though I have tested so many layered materials. The idea of having other projects was really good for me, so I need to say thanks to Andrea for letting me work on many other areas as well.

My PhD has spanned from printed electronics to concrete and biological substrates. We have made active concrete by embedding titanium and layered materials – in particular graphene – inside the concrete to make photoactive concrete that will break down pollution in the atmosphere. We have used graphene as a biological substrate to grow neurons.

I started to work for the Flexible Electronics Work Package within the Graphene Flagship, so I have also worked on making low cost electronics on flexible substrates, from photodetectors to transistors, antennas and solar cells. Within these projects, everything should be flexible, low cost, green and disposable – all at once.

Recently I have also been working on composite materials, to create strain sensors, and wearable electronics. I think that my favourite project was developing graphene strain gauges as I found that they have many applications in everyday life. Strain gauges can do everything – they can measure blood pressure and count the number of steps, they can be used as temperature sensors – they are very versatile. And as an engineer, I want to see the applications! I don't really like to work a lot for nothing,

What made you interested in materials science?

For me, materials science is about solving problems. It's really curiosity about how things are made and how that changes the way that they work – to see how the structure of the material, or how the material is made at the nanoscale could influence the properties, and then the final application. In my Bachelor's and Master's, I studied how nanomaterials can improve the properties of materials such as wood, cement, polymer, concrete and metal. I was really interested in corrosion or similar kinds of applications.

What been you most unexpected result?

I've been to a lot of different conferences and trade fairs as part of my PhD. I really like speaking with people and getting to know new people. In particular, I think that the Mobile World Congress was an amazing experience especially because we interacted with people with completely different backgrounds, who gave us new ideas about how to apply graphene in new fields. For example, I made a nail polish based on graphene. If you polish it becomes shiny, so you have matte and shiny in the same product.

Also, a main result of this PhD has been being able to balance and active life with being a good scientist! I have a lot of results, but I have managed to have a good balance between activities within the college, where I am involved in welcoming new members and organising cultural events and seminars with speakers from all over the world

This has been one of the most important parts of my PhD – learning how to be part of a scientific group but as well learning how to be involved in a large international group.

What are you planning to do next in your career?

That's a good question! I'm borderline between staying in academia and moving to a company, but I always want to do research. In my future work I will try to do something that is linked with going to a lab and making something. I really enjoy being able to see what I have produced in the real world with real applications.

I'm most interested in carrying on working with composites – concrete or plastic or other materials with additional functionalities. Specifically, liquid-phase exfoliated layered materials and graphene are really promising in adding new functionality to composites.

For me, materials science is about solving problems"

Lucia Lombardi