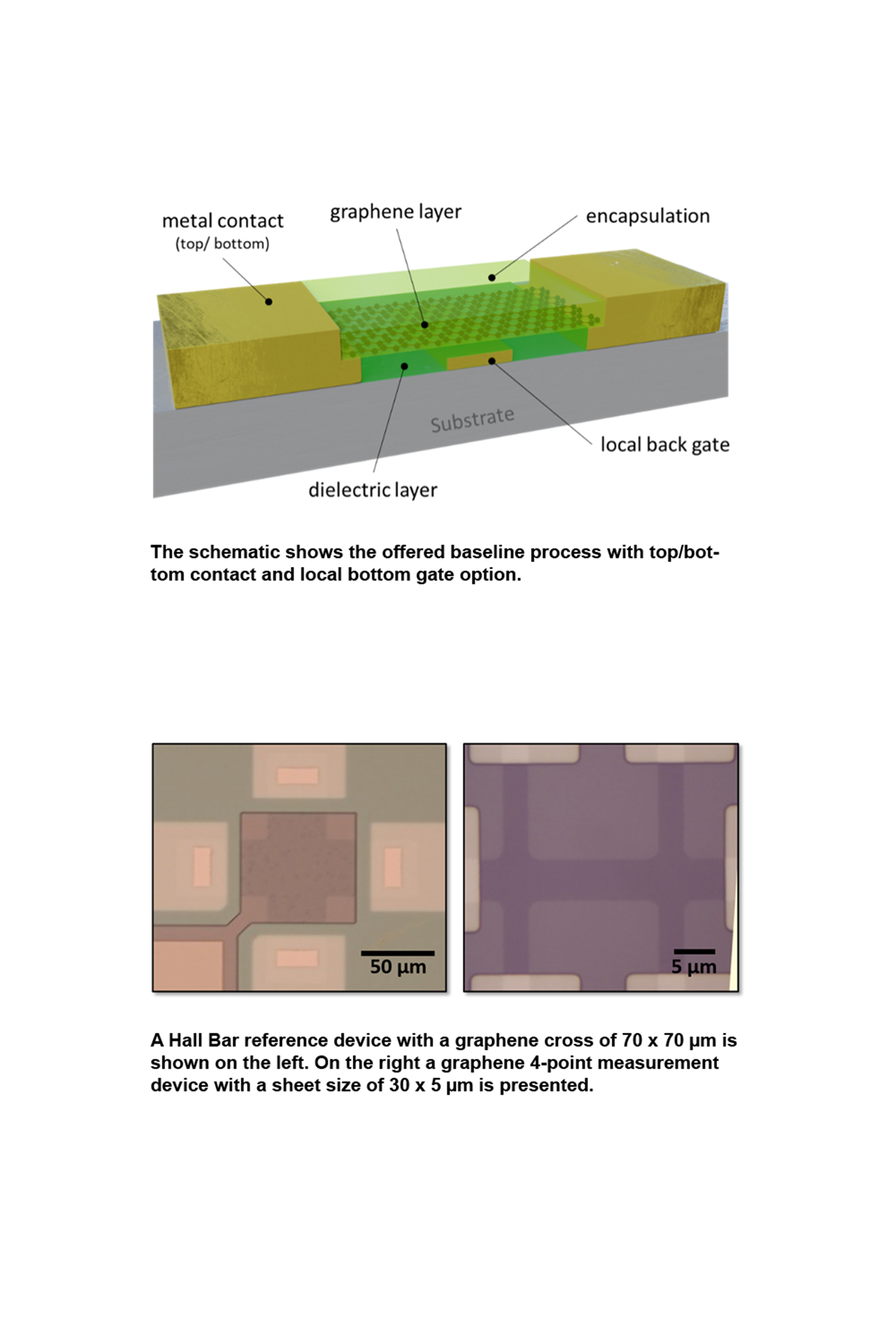

The offered baseline process for the first MPW run is a GFET including a top/bottom contact with an optional local or global back gate, an optional encapsulation and an optional graphene-area opening. The design of the device can be adjusted within the specifications listed below.

Specifications

Substrate

- Material: Silicon, Glass

- Basic die size: 1 x 1 cm² (a different size can be consulted upon individual request)

Resolution

- General design rule: 5µm for in-layer critical dimension and over-layer alignment

Baseline Process

- Top/Bottom metal contact

- Wafer scale graphene transfer

- Basic module provided in PDK: Hall cross, TLM devices, 4-point measurement bar

- Optional: encapsulation, and via opening on top of metal pads

- Optional: graphene sensing area opening

- Optional: metal local or global back gate

Characterization

- Optional: Raman characterization

- Optional: Electrical measurement for as-fabricated devices

Application

- Bio/ Gas/ Chemical sensors, Hall Sensors, Photodetectors