A positive impact start-up specialised in developing few-layer graphene in different media

An interview about Carbon Waters’ success story

Specialty chemicals company, Graphene Flagship Associated Member Carbon Waters, was nominated as one of the start-ups that produce positive impact in the Nouvelle-Aquitaine region (France) and was thus selected to take part in CES 2023, one of the biggest tech events in the world taking place in Las Vegas (US) in January 2023. We speak with Carbon Waters' Project Manager for Formulations & Coatings, Thomas Bottein, and CEO Alban Chesneau.

Congratulations for your great results! Can you summarise Carbon Waters’ achievements over the last five years?

The story of Carbon Waters began in 2017 in Bordeaux (France). After more than ten years of research at the Graphene Flagship Partner CNRS National Centre for Scientific Research, the company was created to industrialise liquid graphene additives.

Our three original patents allowed us to produce graphene with an extremely robust process, substantially reducing potential health and environmental impacts. Basically, we use ions to separate the carbon sheets at a nanometric level, using a process that we call mechanic-ionic exfoliation. This technique obtains perfect graphene sheets (99.95% carbon), without functionalisation or defects, directly in a solvent and without any external additives. From the original 20 ml batches in 2017, we scaled up to several litres and plan to move forward to tons by the end of 2023.

We managed to build an entire quality control to assess the uniformity of our dispersions which contain flakes from two to eight layers. This is a common technical bottleneck when using graphene powders. We also have an applications team that bridges the gap between customer specifications and our products.

What are your products and services?

We sell stable dispersions of few-layer graphene in different media. We provide graphene in solvents, such as water, but also in polymers and resins. We work on all types of thermosets and elastomers depending on our customers’ requests.

Our two main products are Graph’Up W2 and Graph’Up EPO: stable dispersion of high-quality graphene in water for waterborne paint and in a standard liquid epoxy for material reinforcement. These products are already tested and validated by independent companies. Furthermore, we have developed a robust quality control process including, for each batch, UV-Visible and Raman spectroscopy as well as TEM and AFM on a more ad hoc basis.

Along the production of graphene dispersions, we also provide a support service for our customers and partners to help them in the development of proof-of-concepts with tailor-made graphene dispersions and specific performance assessments. Part of the characterisations are done in-house, while we also use the services of technological platforms as we are not equipped for the wide range of applications our customers work on.

Who are your target customers?

We target two types of companies: large end-users’ companies in the aerospace, defence, automotive and energy sectors. These companies are willing to tackle tremendous technical challenges such as electric transportation, hydrogen storage, new defence systems, power electronics or the new generation of satellites. Meanwhile, we work with more traditional industries, such as the paint industry and large chemical companies, willing to discover new properties for their materials at an affordable cost and to accelerate their transition into greener and more effective products.

What’s your unique selling point?

Working on ready-to-use dispersion makes life much easier for industrials that want to work with graphene. Product development is much faster and less expensive. Furthermore, our products show strong added value after months of storage at room temperature since a small percent of our additives allow a substantial increase in anticorrosion protection, a high level of thermal stability and thermal conductivity.

At Carbon Waters, we pay close attention to Health and Safety aspects: we performed the life cycle assessment of our process, we work to reduce CO2 emissions as much as possible, for example by recycling and re-using our exfoliation solvent and decreasing the energy consumption of the different steps. We are also very proactive in the study of the degradability of graphene. All these actions are much appreciated by our customers. Furthermore, since we do not work with powders, we provide a safer environment of our workers and also for our customers.

What’s next?

After many discussions and exciting preliminary results, we decided to focus on replacing toxic additives in paints, reinforcing polymers for aeronautics and automotive industries as well as thermal pastes for aerospace, electronics and batteries. More recently, we were involved in collaborative projects on energy storage. We have obtained very promising results so far!

How are you involved in the Graphene Flagship?

As a small company, it is hard to gain good visibility, legitimacy and access to specific know-how and experts. Since we joined the Graphene Flagship some years ago, we have had very interesting and positive discussions. We have been involved as Associated Members in the Graphene Flagship Work Package for Composites. We have had the opportunity to present our results, discuss with partners and develop a better picture of graphene at the European scale.

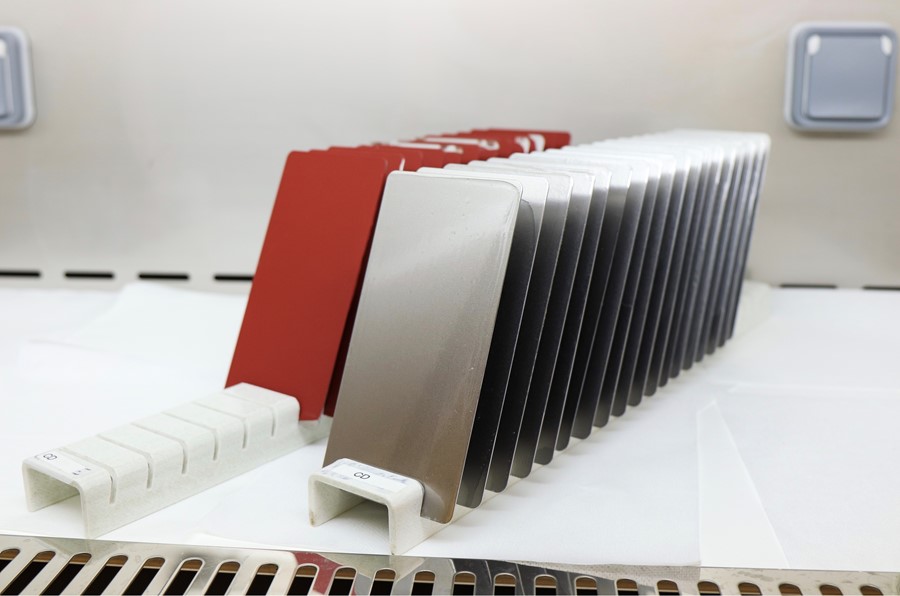

Carbon Waters dispersions are used for a wide range of applications: replacement of toxic additives in paints, polymer reinforcement for aeronautics and automotive industries as well as thermal pastes for aerospace, electronics and batteries (Credit: Carbon Waters).

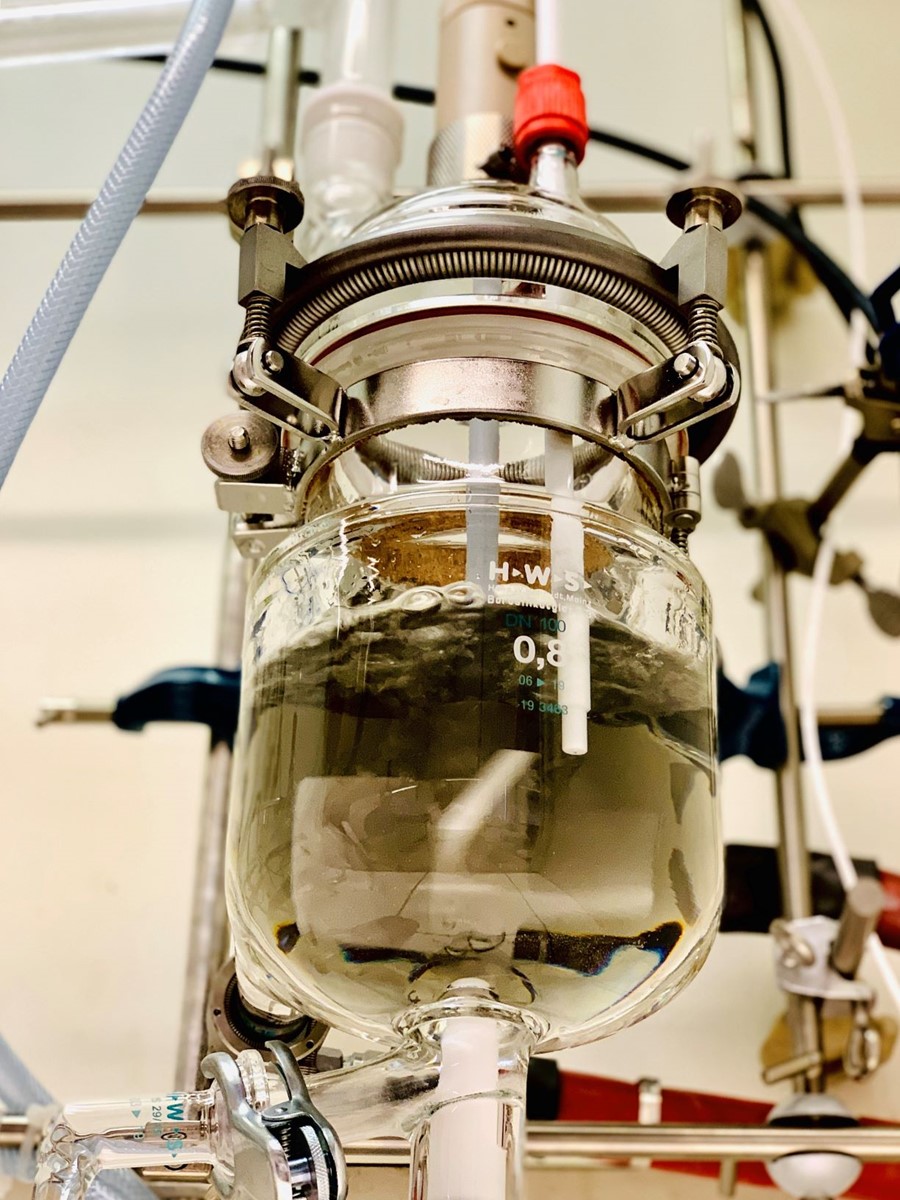

Carbon Waters produces high-quality, stable dispersions of graphene with its patented exfoliation technology (Credit: Carbon Waters).

Varnishes and paints enhanced with graphene show superior protection to reduce water and gas permeation, and decrease corrosion rate (Credit: Carbon Waters).

NA20 start-ups winners 2022