Stretchable graphene conductors for wearable technologies

Replacing metals with environmentally friendly and skin-compatible inks.

A team led by researchers from Graphene Flagship Partner Eindhoven University of Technology in the Netherlands with collaborators from Graphene Flagship Partner VTT Technical Research Centre of Finland Ltd., Pulseforge in the United States and the Hols Centre in the Netherlands has developed a graphene-based ink made of environmentally friendly and skin-compatible chemicals, suitable for wearable technologies.

Wearable technologies (WT) consist of electronic devices that are worn on the surface of the skin or embedded in clothing. WT detect, analyse and transmit information about the body and/or ambient data, and can have life-changing applications in medicine, sports and other fields. They are also becoming an important player in the field of the Internet of Things.

WT’s conductive components are currently produced by printing metal-based inks. However, metals can be expensive (e.g. silver and gold), or may be environmentally unfriendly, and sensitive to oxidation. As an alternative to metals, graphene is an environmentally inert, mechanically strong, abundant, and highly conductive material, and is therefore ideal for incorporation into wearable conductors.

The team used graphene flakes, produced by liquid phase exfoliation of graphite, as a conductive filler. The researchers ensured skin-compatibility through the use of nontoxic solvents, and boosted stretchability and substrate adhesion by adding a stretchable thermoplastic binder of polyurethane.

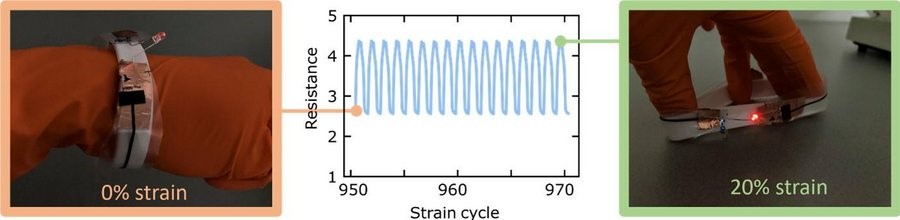

Next, the team produced conductive tracks with different techniques, focusing on screen printing - a technique widely used for the manufacturing of flexible electronics. Printing resulted in stretchable tracks with conductivity levels comparable to other carbon-based conductors. Stretching tests confirmed that the conductors remain conductive even under 100% strain and highly stable over 1,000 cycles of 20-50% strain, which is the strain level of human skin.

The combination of high conductivity, stretchability and durability makes these conductors promising candidates for application in electronic devices that are worn on the skin or integrated in clothing. Examples are wristbands for sweat sensing or pulse monitoring, on-body heaters, smart sportswear and wearable power sources. The stretchability of these devices not only enhances comfort, but also improves their lifetime. Finally, the ink preparation and printing processes employed by the researchers are scalable and can bring high-volume production of stretchable wearable technology into scope.

“This paper describes and validates the fabrication of high-performance stretchable conductor, based on graphene inks. This work paves the way to manufacturing large scale flexible and stretchable wearables systems,” says Henri Happy, Deputy Leader of the Work Package for Flexible Electronics.

“Liquid phase exfoliation and printing of graphene-based inks was pioneered by the Graphene Flagship, and their application for printed and wearable electronics has been the focus of a Flagship Work Package since the beginning of this initiative. These recent results are a testimony of the continuous progress in this area, and bring the technology closer to applications,” says Andrea C. Ferrari, Science and Technology Officer, and Chair of the Management Panel of the Graphene Flagship.

References

van Hazendonk, Laura S., et al. "Printed Stretchable Graphene Conductors for Wearable Technology." Chemistry of Materials (2022). Printed Stretchable Graphene Conductors for Wearable Technology | Chemistry of Materials (acs.org)

Resistance vs strain curve of printed tracks on a wristband demonstrating excellent stretchability and durability of the material over many cycles.

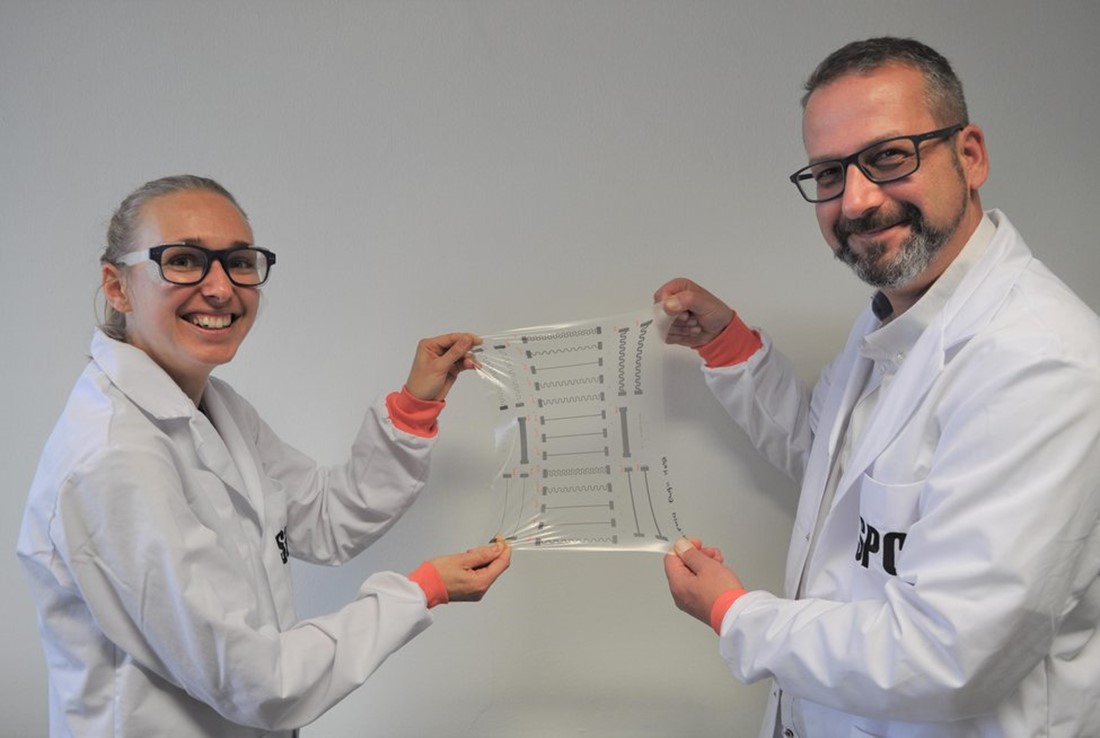

Heiner Friedrich and Laura van Hazendonk from Graphene Flagship Partner Eindhoven University of Technology in the Netherlands.