Functional Foams and Coatings

New materials to tackle sustainability challenges

The Functional Foams and Coatings Work Package took significant steps forward on the functionalisation and processing of graphene and related materials (GRMs) into porous structures, such as foams and membranes, coatings for environmental applications like water and air purification, anticorrosion coatings and environmental monitoring devices. These address the United Nations’ Sustainable Development Goals to fight against the shortage of drinkable water, the increase of air pollution and the lack of proper health monitoring.

The last 10 years

The Work Package has faced some challenges in upscaling functionalised GRMs and their industrial-level processing into foams and coatings. However, these have been successfully addressed and two spin-offs were established, namely Sixonia Tech and BeDimensional.

BeDimensional’s anticorrosion paint based on two-dimensional hexagonal boron nitride and Sixonia Tech’s graphene inks are already on the market.

We filed several patents and coordinated several non-disclosure agreements to discuss graphene-based foams with various European companies, especially in the automotive and aviation sectors.

We have also worked on membranes for water filtration and sensors for environmental and health applications. Finally, we have collaborated with the Spearhead Project GrEEnBaT, led by Varta Micro Innovation, to work on graphene-enabled energy storage solutions.

Last year’s progress

This year we published our progress in developing membranes for reverse electrodialysis – a technique that could capture the osmotic energy available from the difference in the salt concentration between seawater and fresh water. Traditional membranes, such as commercial ion-exchange membranes, suffer from inadequate ion transport abilities, while layered materials have emerged as promising alternatives to generate electricity. These thin membranes made of imine-based 2D polymers display excellent ionic conductivity and high selectivity, resulting in power density of 53 W/m2, which is one order of magnitude higher than traditional ion-exchange membranes.

The team also published a method to develop single crystals of charged two-dimensional polymers made of pyridinium cations and BF4 anions. The crystals have a thickness that can be adjusted between 2 and 30 nm and can be as large as 120 square micrometres. They show excellent chloride ion selectivity and output power density, superior to those of graphene and boron membranes.

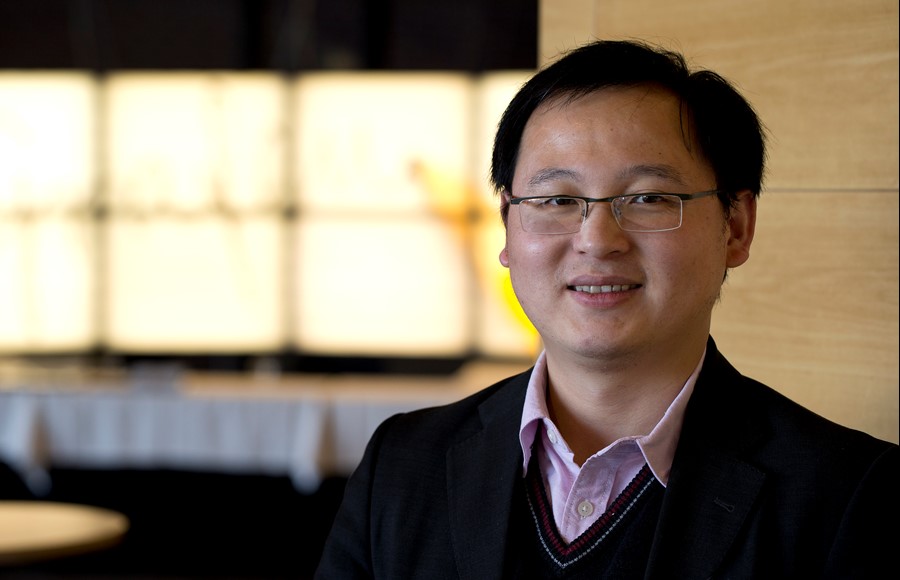

Xinliang Feng, Work Package Leader

We cannot wait to see our technologies on the market in the next five to ten years. These sustainable materials can compete with the state-of-the-art technologies and hold the potential to address global challenges, especially water scarcity, air pollution and human health monitoring.”

Work Package Leader

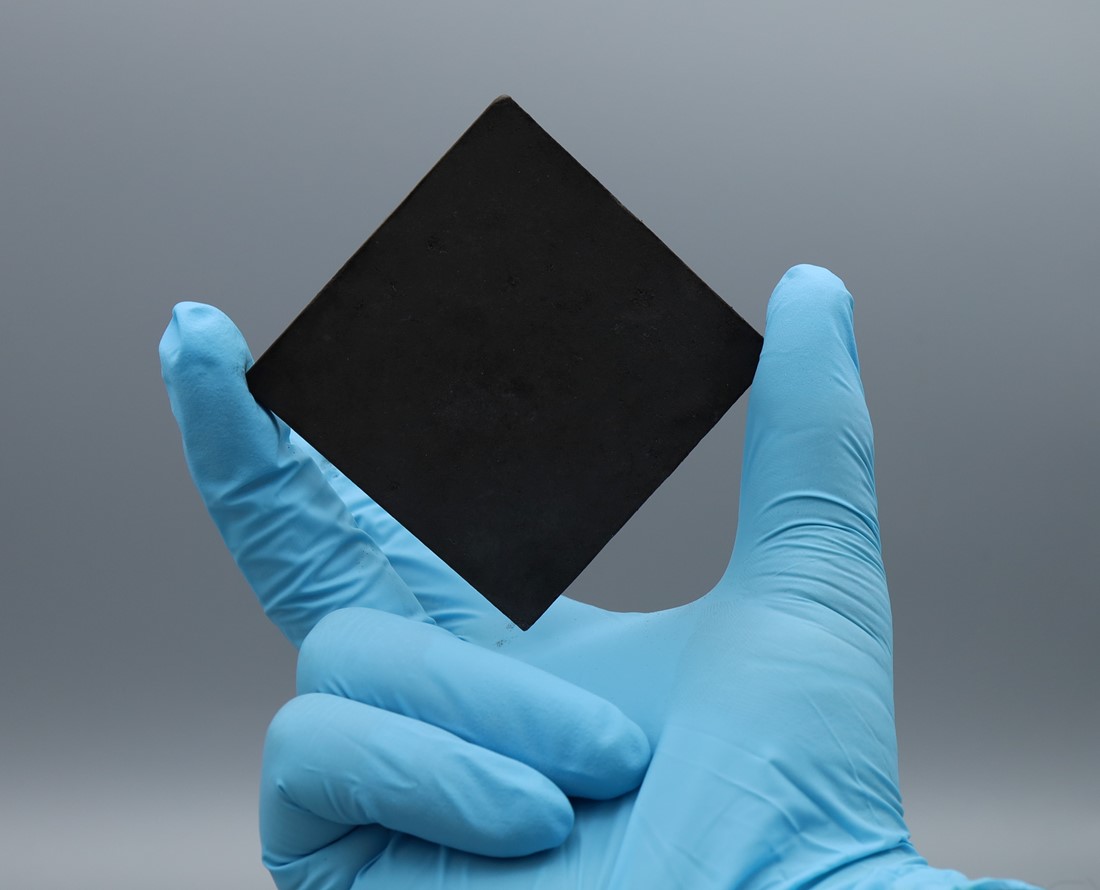

Upscaled aerographene foam used in the AEROGrAFT Spearhead Project’s air filters. Credit: Christian Albrecht Universität

References

Wang, Z. et al. Nature Synth. 2022, DOI: 10.1038/s44160-021-00001-4

Zhang, Z. et al. Nature Commun. 2022, DOI: 10.1038/s41467-022-31523-w

Hou, H. L. et al. Adv. Funct. Mater. 2022, DOI: 10.1002/adfm.202207065

Latest Articles

Overcoming the challenges of water filtration with graphene and layered materials

BeDimensional and Rice University demonstrate destruction of PFAS “forever chemicals” using few-layer hBN

BeDimensional and Rice University achieve significant results demonstrating that few-layer hBN can destroy PFAS “forever chemicals”, among the most persistent and harmful contaminants known, breaking some of the strongest bonds in chemistry.

BeDimensional Presents the First Industrial Implementation of Graphene Heating Paint in Genoa

The event marks the operational debut of the technology, applied in a real-world context through a conductive solution capable of generating heat uniformly and efficiently, confirming BeDimensional’s pioneering role in the energy transition through advanced materials

The ARMS project celebrates its first scientific publication

The GRAPHERGIA Project is "Back to School" at Graphene Week 2025

BeDimensional: The Future of Heating is a Graphene Paint

This revolutionary technology provides energy savings of 40%, on average, compared to traditional electric radiators and is a competitive alternative to heat pumps. A thin, versatile, eco-friendly, and easy-to-install radiant solution.