Bridging the gap between graphene’s quality and processability

Sixonia Tech develops customised formulations with electrochemical exfoliation

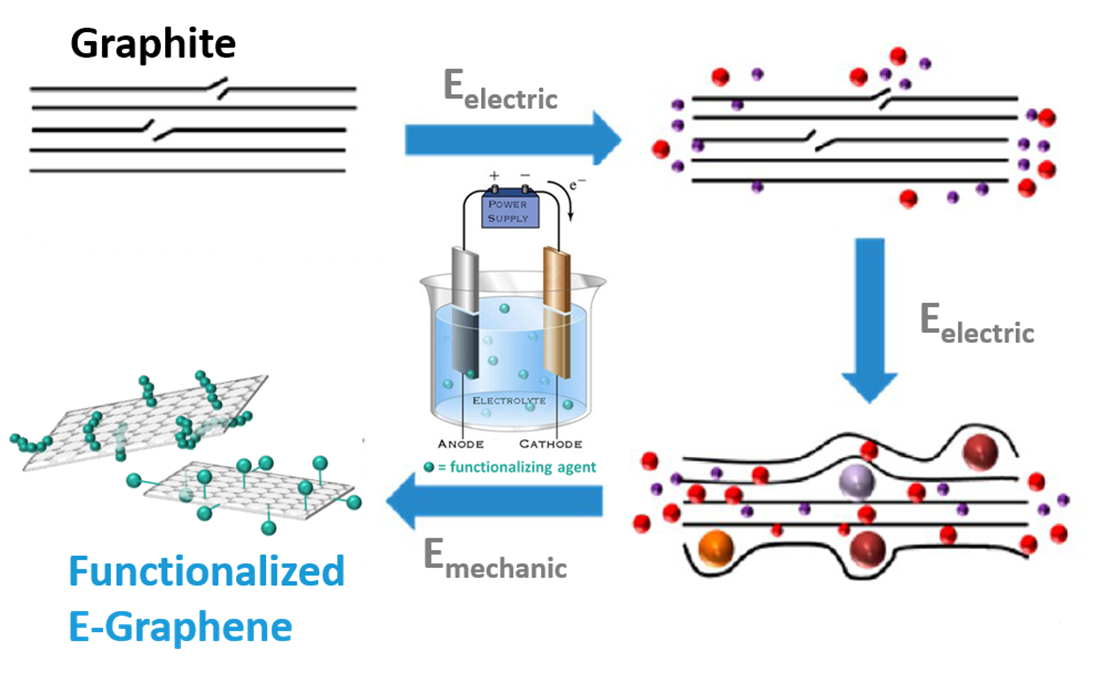

Graphene Flagship Partner Sixonia Tech GmbH’s proprietary technique is an electrochemical exfoliation method where few-layer graphene is derived from graphite and functionalised with the desired chemical groups at the same time. A spin-off from Graphene Flagship Partner Technische Universitaet Dresden in Germany, Sixonia has continuously doubled its turnover every year since its launch in 2017.

We spoke with Martin Lohe, co-founder and CEO of Sixonia, who has worked with the Graphene Flagship since 2015.

Which problems are Sixonia trying to solve in your field? Which solutions are you bringing?

One of the primary challenges with graphene has been its tendency to re-stack back to graphite during processing. To avoid this, people have used additives and surfactants, which could reduce the material's performance. Alternatively, graphene oxide is more processable than high-quality graphene, but is not as electrically conductive.

Sixonia is addressing this issue and integrating the best of both worlds, namely high quality and processability, by functionalising graphene just enough to make it processable, while retaining graphene's features, such as electrical conductivity.

Which are your products and target customers?

At the moment our focus is on being a material provider. We sell E-Graphenes. The “E” stands for our process: electrochemical exfoliation. We use this terminology to distinguish ourselves and our graphene products from other bulk graphene products on the market, which mainly come from either mechanical, such as liquid phases exfoliation (LPE), or chemical processes. Our functionalised few-layer graphenes can be dispersed in various media, including water, without surfactants or other additives. They are currently sold as ready-to-use dispersions/inks, as well as concentrated pastes and other customised formulations.

We are usually engaging with customers who try to integrate graphene into their products or formulations and, in many cases, they have very application-specific requirements. In such cases, we also offer contract R&D services to develop customer-tailored formulations.

What is unique about Sixonia Tech’s strategy?

Our high-quality E-graphenes are easy to use, without need for additives. Beyond our established graphenes, we have the ability to develop customised formulations for our customers. For example, they might be concerned about compatibility with downstream processing steps or other components of their formulations. We are usually able to offer them easy-to-use formulations that integrate smoothly into their existing processes and ensure maximized added value and performance benefits.

Within the Graphene Flagship, who do you collaborate with?

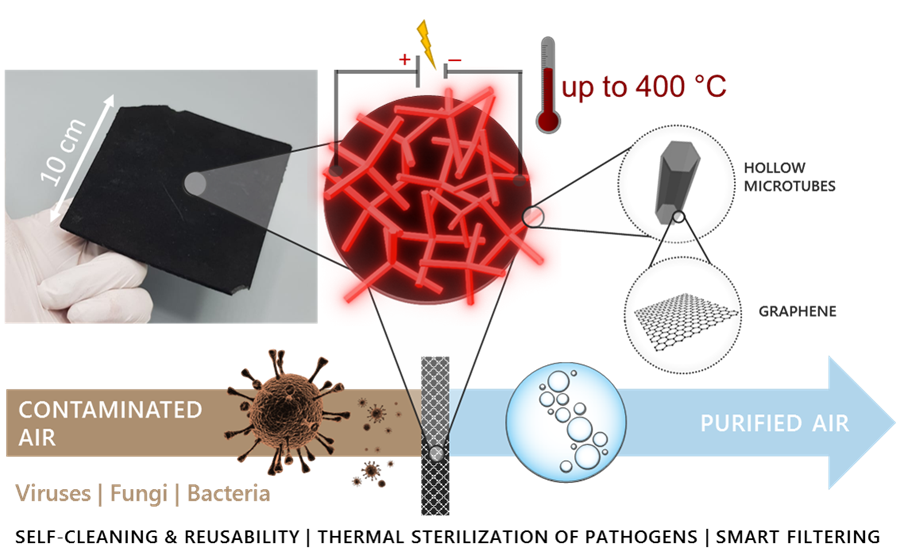

We develop graphene dispersions for anti-corrosion coatings for the academic and industrial partners of the Functional Foams and Coatings Work Package. We also collaborate with the Graphene Flagship Spearhead Project AeroGraFT led by Graphene Flagship Partner Lufthansa Technik, upscaling the production of water-based graphene dispersions for next-generation aircraft’s air filters. We have sent samples to other Graphene Flagship Partners and Associated Members, and we are always open to more collaborations.

What are your goals for the future?

We are finalising the work on our pilot reactor, which will have a capacity to produce ~1kg of graphene per day. This is a major milestone for us, as it will show the scalability of our approach.

We want to strengthen our position as a reliable provider of high-quality graphene for industrial users in different sectors. Currently, we see the most potential in functional coatings for conductive textiles and energy-related applications. We are planning to make our technology available to our customers to produce graphene under a licensing model, which will reduce logistic burdens, and ease their pressure in terms of continuous supply.

We want to keep our growth rate at the current level, expand our team and also gain some more traction in the markets beyond Europe. Gradually we will also move forward from being a pure materials producer to a more vertically integrated company, providing ready-to-use inks and other semi-finished products for different applications.

Sixonia’s collaboration with Graphene Flagship Spearhead Project AeroGraFT to produce air filters (Credit: Sixonia Tech)

Sixonia’s dispersions and inks of e-graphene

Sixonia’s proprietary method to produce e-graphene with electrochemical exfoliation where graphene is formed from graphite and functionalised at the same time. (Credit: Sixonia Tech)