The PolyGraph Project Produces Graphene-Reinforced Polymers

PolyGraph developed a panel for seats in vehicles, comprising an epoxy resin containing graphene which provided improvement to the thermal, mechanical and electrical properties.

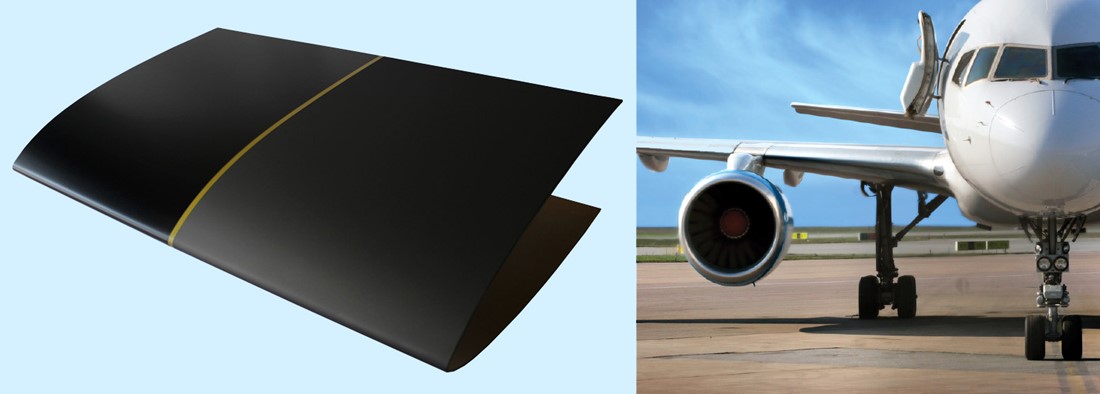

Graphene can be used to make car seats and aircraft antenna protection enclosures lighter, which will reduce fuel consumption. These are just two examples of the uses of this material exhibited during Graphene Week in Athens, where companies and research centres presented their latest results.

Over 500 scientists and experts from 43 countries assembled for Graphene Week in Athens. Under the motto “the future meets the past”, experts presented the latest developments in graphene and related materials.

The meeting, on the 25-29 September 2017, was organised by the European Graphene Flagship to discuss the latest research and applications of graphene and related layered materials.

The Graphene Flagship helps to coordinate graphene and related materials scientists within Europe and promotes collaborations with companies to accelerate the use of graphene in commercial products.

The related European project PolyGraph, a partner of the Graphene Flagship, is a four-year EC funded project which came to an end in October 2017 with 14 partners across Europe: seven SMEs, four companies, two universities and one research centre. Together they developed two demonstrators incorporating graphene that can help reduce the weight of vehicle and aircraft components, resulting in better fuel economy and lower harmful emissions.

One of the devices is a panel for seats in vehicles, comprising an epoxy resin containing graphene, providing improvement to the thermal, mechanical and electrical properties.

The Italian firm Fiat has produced this technology demonstrator through its Centro Ricerche. The UK company NetComposites, the coordinator of the Polygraph project, characterised and manufactured the composite material.

Development engineer, Maria Konstantakopoulou from NetComposites, highlighted the role of the PolyGraph partners in each of the steps required to reach the end product: “Robnor Resins (United Kingdom) supplied the epoxy resin, the Spanish company Avanzare and the Swiss company Imerys prepared graphene, then mixed with the resins using advanced mixing and exfoliation techniques developed by the German SMEs YTRON and NETZSCH.”

Gary Foster, project manager at NetComposites and project manager of PolyGraph, said “We developed process methods for exfoliating expanded graphite and generating graphene at an industrial level. These processes have been used to produce a material with improved physical and electrical properties for composites, coatings and adhesives.”

The second demonstrator was a radome or sonar housing, which is an enclosure to protect an antenna without interfering with radio waves. It is made with fibreglass-reinforced polymers and resins enriched with graphene.

The UK company BAE Systems, one of the leading manufacturers in the European aerospace sector, took part in the design and analysis of this prototype, proving that graphene technologies can now be applied to some components within this industry.

Researchers at Queen Mary University of London (QMUL) also took part in the development of this component: they developed a technique to improve the electrical and thermal properties of polystyrene-graphene nanofibers via electrospinning and offered solutions for filtration problems encountered when incorporating graphene into resins.

The Swedish research institute RISE estimated the costs of the life cycle and the environmental impact – including waste management – associated with the production of the panel for car seats and the radome for aircrafts. They have also tested the effects of fire on these products.

Julio Gómez, the director of Avanzare, stated: “graphene offers very high electrical conductivity and can compete with other materials, such as conductive lampblack.”

Industry standards

Julio Gómez from Avanzare has just been appointed chairman of the Alianza Española en Grafeno (Spanish Graphene Partnership), aimed at bringing producers and users together to ensure standards for the materials being sold. "Graphene-based materials need to be ‘labelled’, indicating how they have been produced and their properties, an essential step for them to be applied in industry" added Gómez.

The PolyGraph results suggest this could be possible. Apart from the two technology demonstrators, a number of PolyGraph partners are considering using graphene in their products.

The PolyGraph project received funding from the European Union’s Seventh Framework Programme for research, technological development and demonstration under grant agreement no 604143. A budget of 7.2 million euros was allocated (5 million from the European Commission). Other partners include Padova University (Italy), the UK company HMG paints, specialising in coatings; the French company SAIREM with its microwave manufacturing technologies and The Institute of Occupational Medicine (United Kingdom), covering health and safety issues associated with the production of Graphene.

Polygraph is one of many projects supported by the European Union in the field of composites. It is also one of the partnering projects of the Graphene Flagship, launched by the European Union in 2013, aimed at getting graphene from the research labs to commercial applications to benefit society as a whole.

-----------------------------------------------------------------------------------------------------------------------------------------------

SINC produces scientific news for the European project SCOPE, coordinated by FECYT and funded by the European Union through Horizon 2020, its funding program. The SCOPE mission is to communicate visionary research results of partnering projects in the framework of the Graphene Flagship and the Human Brain Project, as well as to enhance the FET Flagships partnering environment in the European Union.

This is an edited version of a piece produced by SINC which was first published on September 30 2017 under a Creative Commons Licence.

http://www.agenciasinc.es/en/News/Graphene-set-to-go-from-the-lab-to-the-marketplace

“We developed process methods for exfoliating expanded graphite and generating graphene at an industrial level"

project manager at NetComposites and of PolyGraph,

graphene offers very high electrical conductivity and can compete with other materials, such as conductive lampblack”

Director of Avanzare