2D-EPL: Wafer scale transfer

The Wafer Scale Transfer Work Package is developing a module to transfer high quality 2D materials from the growth wafer to a target wafer for the 2D Experimental Pilot Line (2D-EPL).

This year’s progress

The work package is working with two different kinds of materials: graphene and transition metal dichalcogenides (TMDCs) and thus developing two transfer solutions. For graphene we are investigating wet methods. For TMDCs we are developing a mechanical process. Both approaches require a carrier layer, therefore we also develop cleaning protocols to deliver a clean, intact layer. Finally, the target’s specifications are also investigated to ensure compatibility with the 2D material.

This is the first year of the project, so we are still in development. The products, graphene and TMDCs, on specific substrates have been designed. Tools for their production are under construction and will be validated in relevant environments in the next steps of the project.

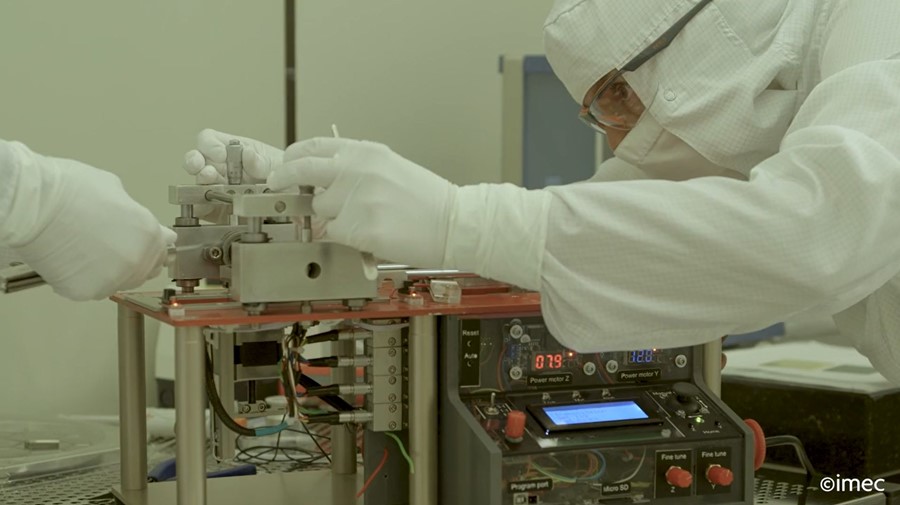

In the past year we also identified water intercalation as being crucial for the delamination of monolayer MoS2 from sapphire and a 300 mm debonder was designed to achieve this goal. We evaluated several adhesives for the different types of transfer that were needed. A debonding prototype to remove the glass carrier at the end of the production process was also built.

imec researchers working on the debonder prototype. Credit: imec

Collaboration

Cooperation between the 2D-EPL partners is crucial to our success. The electrochemical delamination of graphene being a challenge, AIXTRON has produced a new tool that will etch the subtract on which graphene is being grown. This will allow us to automate the transfer of graphene to 200 mm wafers very soon.

Concerning the delamination of TMDC, the collaboration between imec and SUSS led us to design a mechanical delamination tool that provides the option of using water at the interface between the growth carrier and the material.

What’s in store

The cleaning of the 2D layer on the target wafer is under investigation, and we are working toward optimised polymer residue removal. The process needs to preserve the integrity of the layer and its properties.

Furthermore, the work package is working on two separate delamination tools specific for TMDCs and graphene. An impressive feat in and of itself! These should be delivered in the coming year. With these tools we want to make these 2D materials available for the industry.