Five successful companies in the Graphene Flagship

One of the Graphene Flagship’s most fundamental goals is to get new graphene-based products into the hands of consumers.

The Graphene Flagship coordinates research into graphene and layered materials at more than 170 institutions, both academic and industrial, across 22 countries in Europe. Not only this, but a third of our funding is devoted to eleven industry-focused Spearhead Projects, each directed by a leading company in the field – and we recently launched the

2D Experimental Pilot Line (2D-EPL) to integrate graphene and layered materials into semiconductor manufacturing, which could lead to new products for computing and wireless communication. Our devotion to pushing forward the bounds of knowledge, combined with our focus on interdisciplinary collaboration, is why 15 spin-off companies and over 90 products have emerged from the Graphene Flagship since the start of the project in 2013. This number is ever on the rise.

Read on to learn about five successful companies in the Graphene Flagship consortium, and discover how their research takes graphene out of the lab and onto the European market.

BeDimensional and VARTA Microinnovation

Enhancing lithium-ion batteries with graphene

BeDimensional is a spin-off from the Graphene Flagship and our partner institution the Italian Institute of Technology (IIT), Italy. They develop materials based on graphene and two-dimensional crystals for the manufacturing and energy industries. In 2020, they teamed up with IIT and the largest battery manufacturer in Europe, Graphene Flagship partner VARTA Microinnovation, to develop graphene-enabled silicon-based lithium-ion batteries.

Thanks to graphene, their new batteries have a 30% higher capacity than the currently available alternatives and can withstand over 300 cycles of use.

The Graphene Flagship helped to advance this prototype on several fronts. The first ideas for a graphene-enabled battery were sparked during the first phase of the project, and the spin-off BeDimensional was established to supply graphene material for the project. The team has now embarked on a new challenge: to develop a long-lasting sustainable graphene-enabled battery for electric vehicles. This is the goal of the Graphene Flagship Spearhead Project GrEEnBat.

INBRAIN Neuroelectronics

Developing neural implants to treat Parkinson’s and epilepsy

Using smart devices based on an innovative graphene electrode, the Graphene Flagship spin-off INBRAIN Neuro-electronics aims to speed up the development of new graphene-based neural implants to help treat brain disorders like Parkinson’s and epilepsy.

The company, now a partner of the Graphene Flagship, was established in 2019 by Graphene Flagship partners ICN2 and ICREA, Spain. They were awarded €1 million by key European investors to support their research,1 and went on to win an additional €100,000 from Sabadell Bank in a competition against 145 other health-related start-ups and spin-offs.

INBRAIN’s devices decode brain signals with high fidelity, and when paired with artificial intelligence, they could help doctors to determine the best course of action to treat patients. Now, in collaboration with the Graphene Flagship, INBRAIN engineers are testing their technology in large animals – and soon, Graphene Flagship partner the University of Manchester and other top institutions will begin tests in humans.

Graphene-XT

Graphene-based lubricating oil for motorbikes and cars

Scientists at Graphene Flagship partner company Graphene-XT, Italy, developed a new graphene-based lubricating oil for diesel or petrol engines in cars and motorcycles. The team tested their lube in the high-intensity engine of a working motocross motorcycle, in a circuit not far from multiple MotoGP World Champion Valentino Rossi‘s ranch.

Due to its layered structure, graphene acts as a strong and effective lubricant. The atom-thin carbon layers easily slip and slide against each other with very little friction. By adding graphene to their lubricating engine oil, the team improved its performance and stability at high temperatures, reducing wear and tear on the engine. Moreover, all of these effects combined reduce engine noise and fuel consumption.

The team are hard at work on the launch of their first commercial lube product, which they expect will hit the market in the first half of 2021. The lube works in any thermal engine: on wheels, on water or in the air. Graphene-XT hopes to release many more commercial products in the future.

das-Nano

Non-destructive characterisation of graphene and layered materials

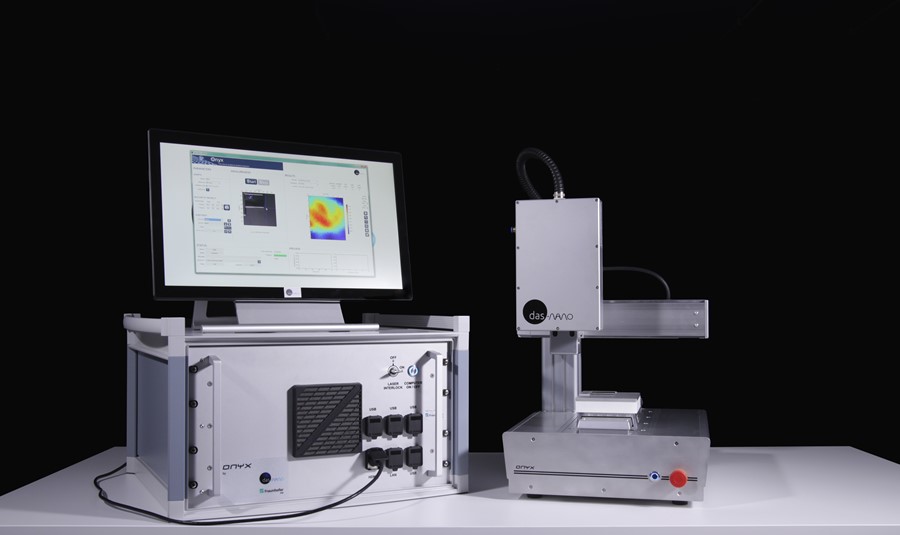

A technology-focused SME and an Associated Member of the Graphene Flagship, das-Nano designs and manufactures Terahertz spectrometers for applications in the automotive and aeronautics industries, for wind power and advanced materials, and more. Their product Onyx is the first system on the market designed to provide full-area, non-destructive characterisation of graphene, thin films and other layered materials.

Onyx covers the gap between the macroscale and the nanoscale, characterising areas from millimetres squared to metres squared, accelerating the industrialisation of materials like graphene and layered materials. It can record spatial resolutions of a few hundreds of microns, enabling the fast characterisation of large sample areas – as opposed to typical microscopic methods like Raman and scanning electron microscopy.

Cambridge Raman Imaging

Developing a graphene-based ultrafast laser for a Raman medical microscope

The scientists at Cambridge Raman Imaging, a new Graphene Flagship spin-off, are developing a graphene-based laser to generate images of tumours inside the body and track their growth or remission, among other applications. The spin-off was established by Graphene Flagship partners the University of Cambridge, UK, and the Polytechnic University of Milan, Italy, and they recently received an investment of €275,000 to support their developments.

Their team are working on a graphene-based ultrafast laser for a Raman microscope. The microscope will generate real-time digital images of tissue samples using Raman spectroscopy, differentiating between healthy and diseased tissue to show the extent of tumours and their responsiveness to treatments. This could also allow a surgeon to make sure a cancer has been completely removed after operation. Furthermore, thanks to the unique properties of graphene and layered materials, their device is based on two synchronised fibre-based ‘picosecond’ lasers: an architecture that is much cheaper than conventional solid-state systems.

15 spin-off companies and over 90 products have emerged from the Graphene Flagship since the start of the project in 2013. This number is ever on the rise.

das-Nano’s Onyx system to characterise graphene, thin films and other layered materials.