What is graphene and how is it used?

Learn about graphene and its various uses in applications ranging from aircraft overhead to cars on the road, and even underground. Graphene's properties can make materials stronger, lighter, flexible and even electrically conductive. That opens many possibilities for new and improved technologies.

Vincenzo Palermo, Director of CNR-ISOF in Italy and former vice-director of the Graphene Flagship, guides us through the Graphene Pavilion. He explains the basic properties of graphene and some key applications for the material.

Graphene is one of the strongest materials in the world. Its chemical structure is similar to that of a chicken wire, but 1 billion times smaller than chicken wire. Being so strong, it is also very thin. It’s 1 atom thin and very flexible.

Because of these properties, 10 years ago Europe decided to invest in a project called the Graphene Flagship where industries and academia work together to transform this material into real applications.

Today, after ten years of work, we can see some examples of these applications. One of the most important sectors where you can apply graphene is in the automotive industry. Here we see a prototype of a Dallara car where graphene has been used in various parts. For example, you could add it to the carbon fibre composites of the car to make it mechanically better, more resistant to impact. But you can also add it to the interior of the car, to the seats for example, to make it safer, more resistant to flame and fire. By adding tiny amounts of graphene in different parts of the cars, you can also reduce the amount of noise and vibrations of the car. This makes it more comfortable.

But graphene is not just useful in automotive applications. In these ten years we have used this technology to make different kinds of prototypes. Here you see just a few examples of them to make new new kinds of cameras, water filters, biological sensors to detect diseases, heaters to purify our air from viruses. There is really no limit to what this technology can do.

Another sector very important for Europe, and for all of us, is aeronautics. Also here, graphene researchers have collaborated with key companies like Airbus to add graphene to the aeroplane. By adding graphene to the fuselage of the aeroplane, you can again improve its mechanical properties making it more resistant to, for example, the impact of birds which is a serious issue for aeroplanes.

But beside just improving the mechanical properties, you can even add new functionalities to materials. One key problem in aeroplanes, besides birds, is the formation of ice. If ice forms on the wing of the aeroplane, the aeroplane can crash. So it’s very important to avoid the formation of ice on the wing. By adding tiny amounts of graphene to the wing, we could heat it, make it electrically conductive, avoiding in this way, the formation of ice. Scientists and industries have together created these kinds of prototypes that when tested in a wind tunnel were found to work. So we can really avoid the formation of ice, making aeroplanes safer and better.

It’s not just automotives, it’s not just aeroplanes, you can really use graphene in lots of different applications.

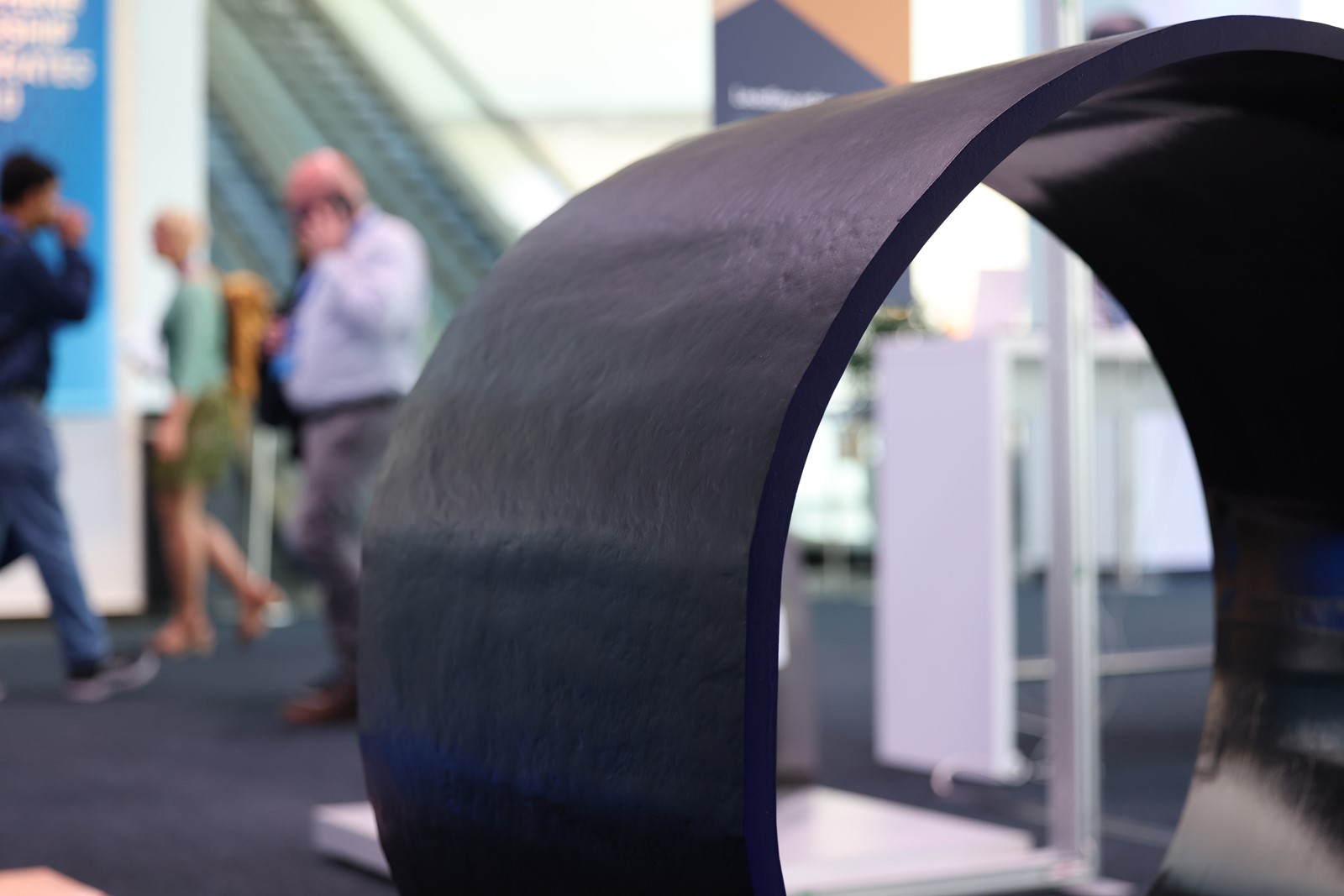

One example is as a replacement for metals in lots of applications. Here we move from the sky, going underground. This is a piece of a huge pipe that would typically be manufactured from metal and used underground. But metal is expensive and can be corroded. It could also be produced from plastic, but it needs to be conductive and also resistant. That’s where graphene comes into play.

This is a material, made by a company of the flagship called Avanzare, where graphene has been added to a polymer to make it more resistant and electrically conductive. In this way, we can use this kind of material instead of metal for these kinds of pipes.

From very small devices to large scale applications, cars, pipe networks and aeroplanes, graphene can really really be used in lots of different fields. And here in the Graphene Flagship we have produced demonstrations that this technology can truly work with the industries in Europe and in the world.

The Graphene Pavilion