Increasing EU consumers’ confidence in tap water with graphene-enabled filters

Graphene removes emerging contaminants from water

Graphene Flagship Partner Medica S.p.a. produces filters based on hollow fibre membranes for various applications, ranging from blood purification to water filtration.

We spoke with Letizia Bocchi, Research Laboratory Manager and leader of the Spearheard Project Graphil, to learn how Medica Spa decided to integrate graphene in water filters.

When did you start to investigate graphene?

In 2015 we were working with Graphene Flagship Partner, National Research Council (CNR) researchers in Bologna, Italy, on another project involving the application of our membranes. The team in Bologna was studying graphene, and this gave us the idea to put our membranes together with graphene. Even though our first few tests only worked for an hour, we saw the potential of combining the two. The filter could capture contaminants from water thanks to its high contact surfaces and chemical affinity with many different chemical species.

What is your goal?

The goal is to obtain a compact water filter, exploiting the best of the two materials: the hollow fibre membrane to eliminate microbiological contaminants (i.e. bacteria, viruses, endotoxins) and graphene oxide to remove emerging contaminants from water.

What are emerging contaminants?

These comprise drugs, antibiotics, pesticides, heavy metals and personal care byproducts. They are called "emerging" because there is an emerging concern about the presence of such contaminants in drinking water. We aim to avoid multiple filtration steps and have all functions integrated into one device that can be installed directly into a household sink or portable water bottles.

Are you trying to reduce the consumption of plastic bottles?

Unfortunately, the use of plastic bottles for drinking water is still very common. In Europe, the quality of tap water can be much more controlled than bottled water, so it is important to increase consumers’ confidence in tap water. At present, our filter is also made of plastic, but the goal is to make it last as long as possible, in order to generate fewer scraps and less plastic waste.

What about safety?

We are working with Safegraph, another Spearhead Project of the Graphene Flagship, to assess the ecotoxicity and cytotoxicity of graphene oxide if released from the filters. We have had excellent results on the safety profile so far. This encourages us to go ahead in manufacturing and developing these filters.

Who do you collaborate with?

We have paired up with other Graphene Flagship Partners, such as the French membrane manufacturer, Polymem, which works with other types of hollow fibre membranes, and the British company, Icon Lifesaver, which sells filters to use in emergency situations like making river water safe and potable. We continue to collaborate with Graphene Flagship Partner CNR in Bologna, and we joined forces with Graphene Flagship Partners Chalmers University of Technology (Sweden) and the University of Manchester (UK). By collaborating with these particular partners, we ensure a complementary set of skills from both companies and universities.

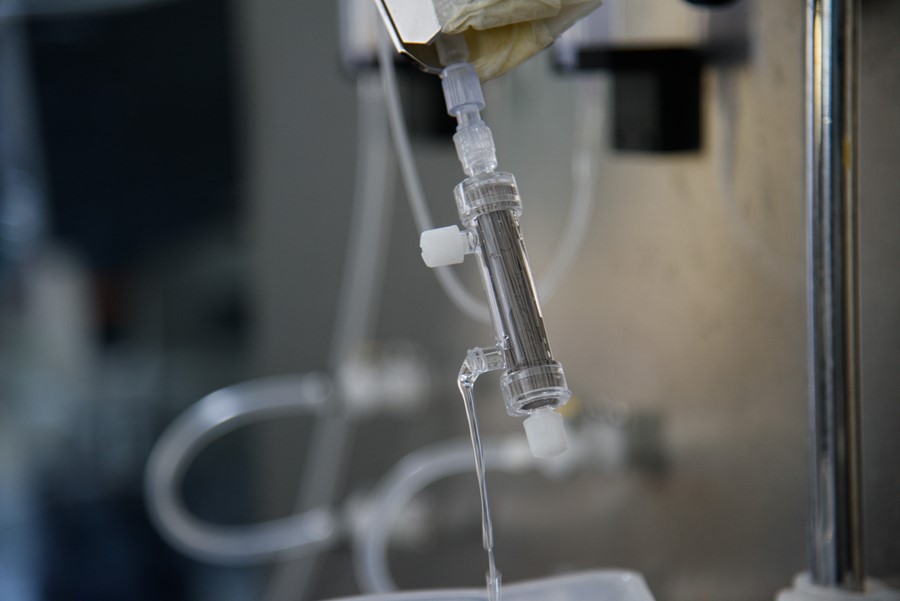

Lab-scale prototype of GRAPHIL filters under testing (credit Medica SpA)

Point of Use filter (credit Sofia Järbur)