Waterproof contacts for graphene electronic circuits

The electrical contact resistance at metal–graphene interfaces can significantly degrade the properties of devices. Graphene Flagship researchers observed that when graphene is integrated with the metal of a circuit, its contact resistance is not impaired by humidity. This will help develop new sensors with a significant cost reduction.

Sensors are one of the many potential applications areas for graphene, an atomically-thin sheet of carbon atoms with high conductivity and mechanical properties. Sensors are devices that transform environmental parameters into electrical signals that can be measured and processed by a computer.

Due to its two-dimensional structure, graphene-based sensors are extremely sensitive and promise good performance at low manufacturing cost. To achieve this, graphene needs to make efficient electrical contacts when integrated into a conventional electronic circuit. Such contacts are crucial to any sensor and significantly affect its performance.

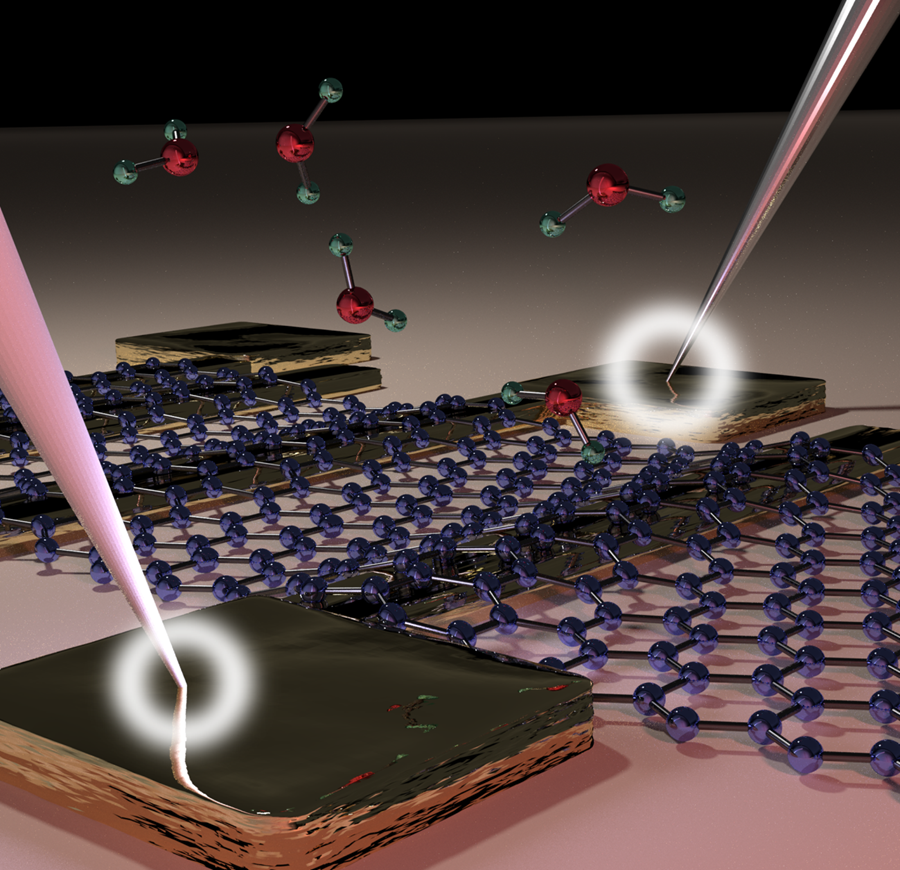

With graphene sensors, a problem arises: the material is sensitive to humidity, thus the water molecules in the air can be adsorbed onto the surface of the sensor. These molecules change the electrical resistance, triggering the appearance of false signals.

Swedish scientists working at Graphene Flagship Associate Member KTH Royal Institute of Technology have found that when graphene is contacted to the metal of electronic circuits, the contact resistance is not affected by moisture.

"Our work will make life easier for sensor designers, since they will not have to worry about humidity influencing the contacts, just the influence on the graphene itself," explains Arne Quellmalz, a PhD student at Graphene Flagship Associate Member KTH Royal Institute of Technology, Sweden, and first author of this paper.

This study, published in ACS Applied Materials & Interfaces, has been carried out using graphene together with gold metallization and silica substrates in transmission line model test structures.

"By combining graphene with conventional electronics, you can take advantage of both the unique properties of graphene and the low cost of conventional integrated circuits," says Quellmalz. "One way of combining these two technologies is to place the graphene on top of finished electronics, rather than depositing the metal on top the graphene sheet."

As part of the European CO2-DETECT FLAG-ERA project, the authors are applying this new approach to create the first prototypes of more efficient graphene-based sensors. More specifically, their purpose is to measure carbon dioxide (CO2), the main contributor to global warming, by means of optical detection of mid-infrared light. Thanks to the advances carried out within the Graphene Flagship, these new CO2 sensors detectors would be cheaper than other alternatives.

In addition to the KTH Royal Institute of Technology, Graphene Flagship Associate Member SenseAir AB, Sweden and Graphene Flagship partners AMO GmbH, and ICN2, Spain, are all participants within the CO2-DETECT project.

Schematic of a graphene device with a contact resistance that is not altered by the water molecules adsorbed on its surface. Credit: Anderson D. Smith