Graphene-enabled solar farm shines in performance

Solar panels comprising perovskite, graphene and related materials demonstrate their potential in outdoor tests.

Outdoor testing of the first solar farm fabricated using perovskites and graphene, yielded a peak power output of 250 W, similar to that of commercial 60-cell silicon solar panels. This is a milestone toward the commercialization of this new technology, allowing for full control of the supply chain.

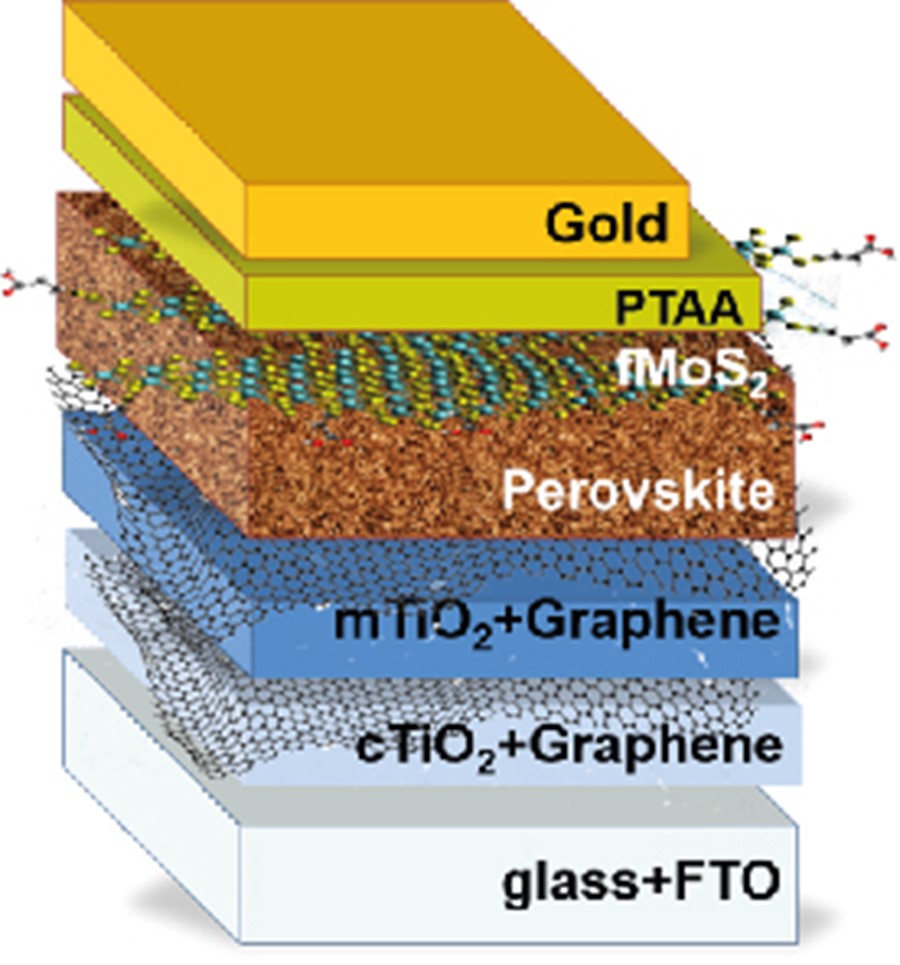

Graphene Flagship Partners Hellenic Mediterranean University, Greece, University of Rome Tor Vergata, BeDimensional S.P.A., Greatcell Solar Italia SRL, Italian Institute of Technology and the National Research Council, Italy engineered multiple solar panels by stacking layers of perovskite, graphene and molybdenum disulfide. Perovskite solar cell technology has low (<0.4 euro/Watt peak) manufacturing costs, while the other layered materials help to extend the device’s life and power conversion efficiency, similar to state-of-the-art silicon solar cells, which can convert around 26% of Sun’s energy into electricity.

The Graphene Flagship team integrated nine graphene-perovskite solar panels for a total area of 4.5 m2 and installed them in Heraklion (Crete), together with the necessary power electronic components, a data acquisition system and a weather station. The solar farm achieved remarkable performance and stability within the first nine months of operation: it retained 80% of its initial power output after eight months. Between June 2020 and June 2021, this solar farm would have produced about 376 kWh.

“We demonstrated that the use of layered materials, such as graphene and molybdenum disulfide, can improve the perovskite solar cells’ interface properties, not just on the lab scale, but also on large-area panels tested in real conditions, thus pushing the Technology Readiness Level to high values around 6-7,” says Aldo di Carlo, from Graphene Flagship Partner University of Rome Tor Vergata.

Since temperature affects the performance of solar panels, the Graphene Flagship researchers analysed how the graphene-perovskite panels compare with commercial technologies at high temperatures up to 70°C. Compared to commercial technologies, these graphene-perovskite panels showed the smallest drop in performance at temperatures up to 70°C, which is a promising result for the realization of photovoltaic systems in South Europe.

“Improving efficiency and stability of perovskite solar panels with graphene and layered materials is one of the goals of the Graphene Flagship,” says Francesco Bonaccorso, from Graphene Flagship Partner BeDimensional S.p.A.

A Life Cycle Assessment (LCA) was also performed to evaluate the sustainability of the solar panels’ manufacturing, lamination, and installation processes, according to ISO 14040-14044 standards. The Graphene Flagship researchers identified that the evaporation of gold in the back electrode is the least sustainable step in the production of these solar panels. The LCA model shows that substituting gold with graphene reduces the environmental impact. Producing 1 kWh with this improved solar farm has an environmental footprint about 50% lower than current European electricity mixes.

“I expect that this successful result, born from the collaboration among Graphene Flagship’s industrial and academic partners, will make an impact on the European energy sector,” says Emmanuel Kymakis, from Graphene Flagship Partner Hellenic Mediterranean University.

“This is a practical example of a successful translation of basic science into industrial application achieved by the Graphene Flagship consortium. It demonstrates that the graphene-perovskite technology is a new solution to shape the energy transition,” says Vittorio Pellegrini, Leader of the Division Energy Composite and Production of the Graphene Flagship.

Andrea C. Ferrari, Science and Technology Officer of the Graphene Flagship and Chair of its Management Panel, adds: “This first solar farm based on a new technology enabled by graphene and related materials exemplifies the progress along the Graphene Flagship technology and innovation roadmap. This is a turning point, and we expect industrial uptake to follow over the next few years, both in terms of new start-up companies and adoption from established enterprises”

Reference:

Pescetelli, Sara, et al. "Integration of two-dimensional materials-based perovskite solar panels into a stand-alone solar farm." Nature Energy (2022): 1-11. https://www.nature.com/articles/s41560-022-01035-4

Graphene-perovskite solar panels with some members of the research team of Graphene Flagship Partner Hellenic Mediterranean University.

The solar panels consist of several layers: glass with fluorine-doped tin oxide (FTO), compact TiO2 with graphene, mesoporous TiO2 with graphene, perovskite, functionalized MoS2, poly(triarylamine) (PTAA) and gold. In the scale-up and sustainable mass production of this technology, gold can be replaced by graphene, other carbon materials or cheaper metals.