Graphene Interface Engineering for Large Area, High Efficiency Solar Cells

Perovskite-based solar cells have record high efficiencies converting solar energy to electrical power, but suffer efficiency reductions at large areas. Researchers in the Graphene Flagship have overcome these limitations with graphene, making large area solar cells with superior performances.

Graphene and other layered materials are opening up new opportunities for improving efficiency in many technologies, such as solar cells. Perovskite-based solar cells have highly efficient solar power conversion, but suffer drawbacks such as reduced lifetime and poor performance at large scales. Now, researchers from the Graphene Flagship have graphene and related materials (GRMs) to overcome these drawbacks, by engineering of the interfaces between the solar cell layers. The result is a large scale solar cell module with a light-collecting active area of 50.6 cm2 and record power conversion efficiency (PCE) of 12.6%, paving the way for commercial perovskite solar cells.

The research, published in ACS Energy Letters, represents a collaboration between leading solar cell researchers in the Energy Generation Work Package of the Graphene Flagship from the University of Rome Tor Vergata, Italy, the Italian Institute of Technology (IIT), Italy, and the Technological Education Institute (TEI) of Crete Heraklion, Greece. The Graphene Flagship aims to translate graphene's unique combination of properties into new technologies that will have benefits to society.

Improving energy technologies is critical for sustainable energy generation as energy demands rise. "The mission of the application-driven Energy Generation Work Package is to develop GRM-based building blocks for solar and fuel cells and to integrate them into large area power generating demonstrators, in order to clearly evaluate the most promising technologies that can be pushed sufficiently far towards up scaling and industrialization," said Emmanuel Kymakis, co-author of the study and deputy of the Graphene Flagship Work Package Energy Generation.

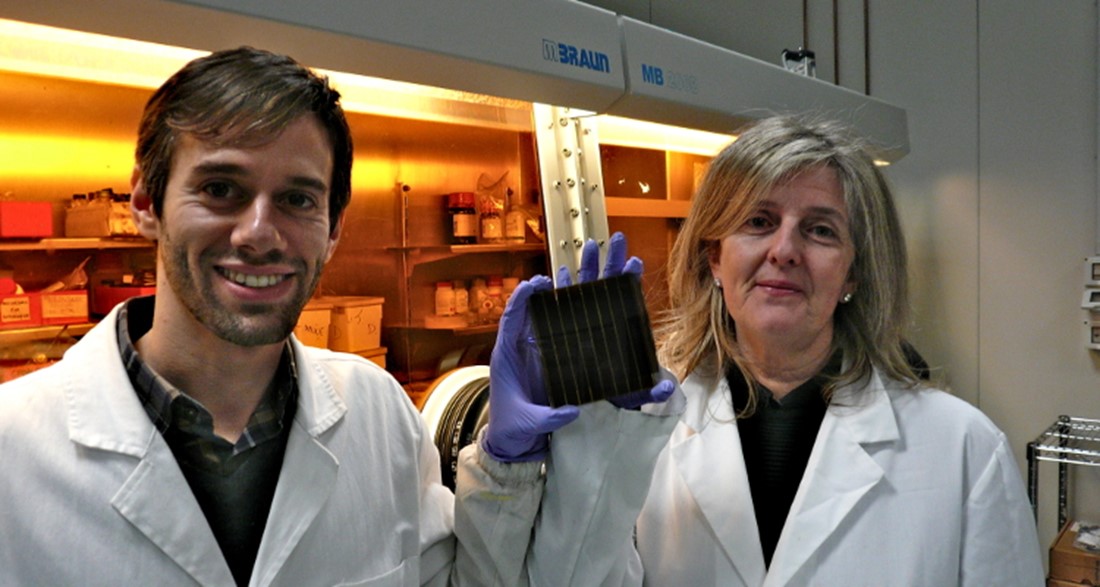

Antonio Agresti and Sara Pescetelli demonstrate the large area solar module.

Large area solar cells

The high performances of perovskite-based solar cells have been achieved in small area cells, with active areas typically around 1 cm2. For solar cells to be viable as a commercial energy generation technology, large scale solar modules must be available to harvest sufficient quantities of light. Due to difficulties in uniformly depositing the solar cell layers, large area perovskite solar cells normally suffer poor interfaces between layers, leading to short circuits, charge recombination and ion diffusion. "Scaling perovskite solar cells is a critical issue. Beside the quality of the materials, it is mandatory to control the uniformity of the deposition and the quality of interfaces all over the size of the module," said Aldo Di Carlo (University of Rome Tor Vergata), co-author of the work. "For this reason, the introduction of GRMs, to control the interface properties and improve, at the same time, the uniformity of the deposition is a winning strategy that can be scaled up at the industrial level."

This work shows that such problems can be overcome through graphene interface engineering. By integrating GRMs, the researchers successfully produced high-performance modules of eight connected solar cells, with a total active area of 50.6 cm2. As well as record PCEs of 12.6%, the modules also showed excellent stability and longevity performance, retaining up to 91% of the initial PCE after 1630 hours.

Scalable GRM interface engineering

Perovskite-based solar cells are made up of thin layers of different materials, each playing a different role in the conversion of light to electrical power. Solar energy is converted to free charges in the perovskite layer, which travel through the cell to produce the current output. Two different types of GRM material were used to boost the charge transport from the perovskite to the electron-collecting titanium dioxide (TiO2) layer in two different ways: mixing graphene flakes into the TiO2 layer and adding an interfacial layer of lithium-reduced graphene oxide between the perovskite and the TiO2. Both additions boosted the PCE, while the graphene flakes also significantly enhanced the lifetime of the cell.

To commercialise this technology, the production methods must be scalable to industrial quantities. Perovskite solar cells are typically produced using solution processing methods. GRMs and other layered materials are readily available as inks and dispersions via simple exfoliation methods, and processed in multiple different ways. "The possibility to produce GRMs in ink form is ideal for the realization of thin interface between different solar cell components" said Francesco Bonaccorso (IIT), co-author of the study. "This approach significantly improves the performances of solar cells, and coupled with the prospective upscaling of ink production and deposition can boost the commercialization of this technology."

GRM Toolbox

This result is a critical step forward toward the commercialisation of high efficiency solar cells, showing that GRMs are making a significant difference in energy technologies. The wide range of GRMs and layered materials suggest further potential for tailoring the interface properties. Kymakis added "GRM are a fascinating toolbox for mastering the interface properties not only in small area but also in large area devices. Our future work will focus on increasing the sizes and lifetime of the modules, and even constructing a GRM–perovskite solar farm."

Gérard Gebel (French Alternative Energies and Atomic Energy Commission (CEA), France) is the leader of the Graphene Flagship Division Energy, Composites and Production, and of the Work Package Energy Generation. He said "Research into energy generation in the Graphene Flagship is application oriented, with a special focus on upscaling to produce large scale demonstrators to convince industrial partners of the added value of introducing GRMs in their devices. This work is clear demonstration that our approach is the shortest way to reach markets."

Andrea Ferrari, Science and Technology Officer of the Graphene Flagship and Chair of its Management Panel, added: "This is the kind of result the Flagship aims for in the present phase: scaling up key technologies by exploiting graphene and related materials. This could pave the way for a large demonstrator solar farm during the next stage of the Flagship. It is exciting to see our project partners steadily progressing across the GRM technology roadmap."

Further Reading

N. Balis, E. Stratakis, E. Kymakis, Materials Today, 19, 580 (2016)

The possibility to produce GRMs in ink form is ideal for the realization of thin interface between different solar cell components"

Co-author of the study