Automotive

Graphene Flagship’s innovations in automotive technology accelerate green mobility

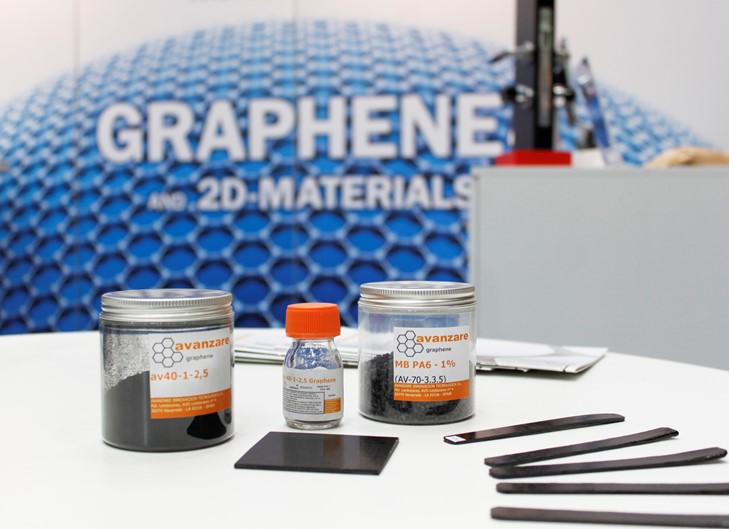

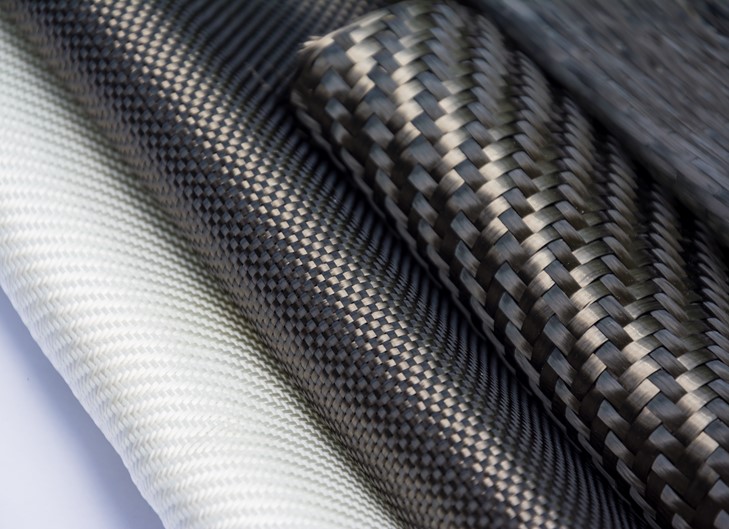

Graphene has the potential to drive significant advancements in the automotive industry — from strengthening structural components to improving electrochemical energy storage (i.e., Batteries) efficiency and safety in electric cars as well as enhancing the performance of the self-driving car. The Graphene Flagship has orchestrated a number of projects researching the benefits of graphene in automotive applications and how vehicles can be improved. The Graphene Flagship is now seeing this research and development come to fruition.

Ultimately, these projects feed into the United Nations (UN)’s 17 Sustainable Development Goals. Objectives include using graphene-enabled products to ensure good health and wellbeing, affordable and clean energy, sustainable cities and communities, responsible consumption as well as improvements to industry innovation and infrastructure in Europe. For the automotive sector, projects include a wide range of end applications for vehicle features and installations which has the potential to improve sustainability in the market.

Related news

Graphene Flagship’s innovations in automotive technology accelerate green mobility

Investing big in Graphenest: Portuguese nanotechnology company raises 1.8€ million for graphene-based innovations

The disruptive potential of Graphenest's graphene-based EMI shielding solutions has attracted significant financial investment

Nanografen is making automotive vehicles more eco-friendly – here’s how

Nanografen, a nanotechnology R&D company and Graphene Flagship partner founded in Turkey in 2013, is finding clever ways to recycle old tyres into graphene applications. Representatives of Nanografen recently shared their work with a wide range of stakeholders at JEC World 2023, where the company was also a finalist for an award.

Graphene applications: AUTOVISION

Graphene Flagship Spearhead Project AUTOVISION is developing a new high-resolution image sensor for autonomous vehicles, which can detect obstacles and road curvature even in extreme and difficult driving conditions.

Graphene applications: G+BOARD

Graphene Flagship Spearhead Project G+BOARD aims to create the dashboard of the future. Unlike existing vehicle dashboards, many of which use metal, the inclusion of graphene-based materials in the vehicle dashboard can significantly reduce the weight of the vehicle.

Towards safer driving in adverse weather conditions

An interview with Qurv’s CTO about wide spectrum image sensors for computer vision applications in self-driving cars and other mass-market autonomous systems.