Energy Generation

Next gen solar cells

The Energy Generation Work Package addresses different approaches for energy harvesting: harnessing the energy of the sun with large-area photovoltaics and producing hydrogen with water electrolysers.

The last 10 years

This ten-year journey allowed us to bridge the gap between laboratory prototypes and up-scaled demonstrations, targeting applications in large-area solar panels for on-grid electricity generation, and flexible solar modules to power Internet of Things (IoT) devices. We developed various graphene and related materials (GRMs) and integrated them with perovskite solar cells to enhance both stability and efficiency. Technical issues that had slowed down the photovoltaics upscaling process have been resolved, including the replacement of noble metals, the processing of titanium dioxide at low temperatures and the optimisation of laser patterning. Moreover, GRM-based conductive pastes and novel encapsulants led to stable and efficient modules with low capital expenditure (CAPEX).

On the fuel cell front, we developed graphene-enabled supports for electrocatalysis. Initially, they were meant to promote only the oxygen reduction reaction, but at a later stage, electrocatalysts featuring a graphene-based support were also developed to promote the hydrogen evolution reaction and the oxygen evolution reaction at low-temperatures. We also devised graphene-based anticorrosion coatings, as well as easily scalable solid-state and liquid-based approaches to obtain enough inexpensive graphene. The resulting demonstrators showed an outstanding performance and durability in the electrochemical processes.

This year’s progress

The Energy Generation Work Package’s effort led to the world’s first outdoor demonstration of a solar farm with 4.5 m2 graphene–perovskite panels. These delivered a peak power exceeding 250 W and demonstrated a remarkable stability: only a 20% reduction in the performance over eight months. Gathered in an open data repository, all experimental data will be of interest to the photovoltaics industrial sector and will lay the groundwork for commercialisation targets. We reached high technology readiness levels (TRLs); TRL 6 in the solar farm demonstration, TRL 4-5 in the transparent conductive electrodes based on exfoliated graphene hybrids, and TRL 5 in the fully printed, flexible perovskite solar modules with stabilised output power for indoor applications. Finally, a life cycle assessment (LCA) model indicated that this technology might compete with those calculated for European 2050 electricity mix scenarios.

We devised graphene-enabled electrocatalysts that promote key processes for the operation of fuel cells and electrolysers, exhibiting a performance and durability beyond the state-of-the-art. These are also free from or with minimal concentrations of strategic elements, such as platinum group metals.

The GRM-enabled functional components, mostly supports and electrocatalysts, have already been synthesised in batches of 5-100 grams and could easily be scaled up. Such functional components are already available on the market for demo purposes and sampling by one of our industrial partners, BRETON.

Emmanuel Kymakis, Work Package Leader

A new generation of scientists was trained, becoming proficient in a hot field with profound implications for the future of mankind.”

Work Package Leader

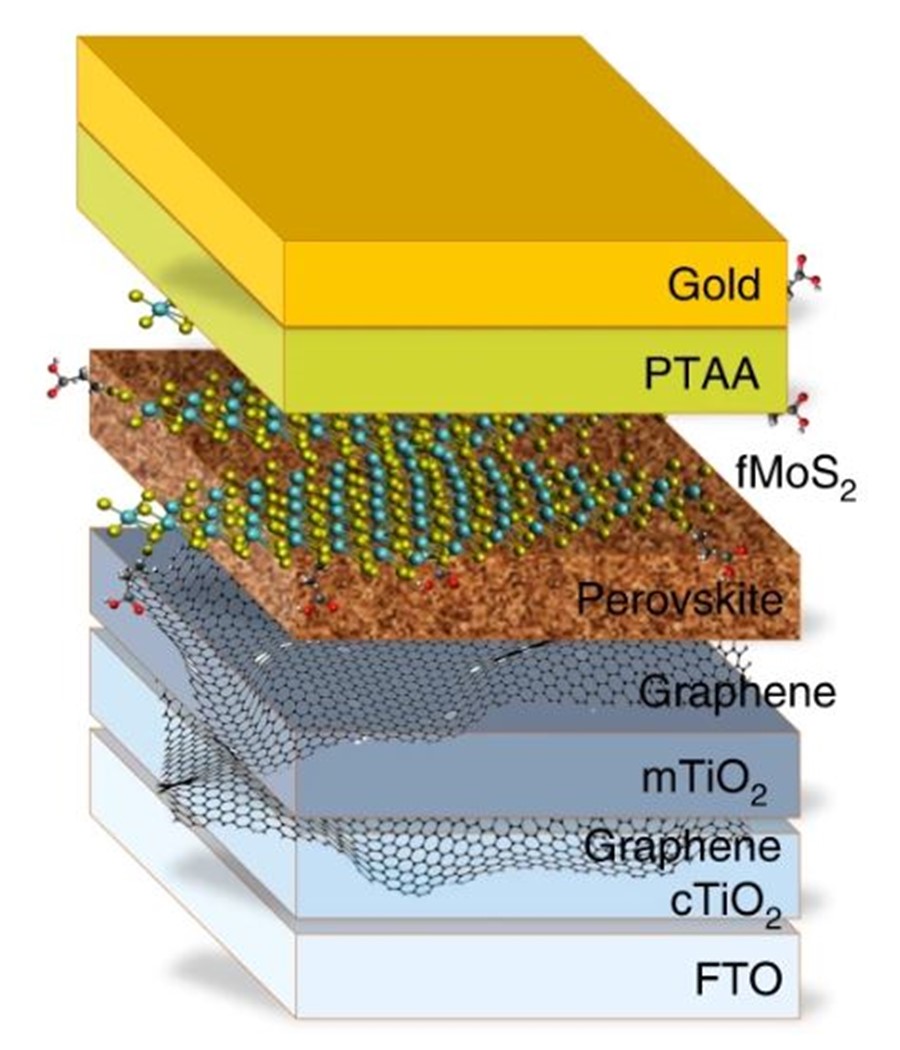

The solar panel consists of several layers: glass with fluorine-doped tin oxide (FTO), compact titanium dioxide (TiO2) with graphene, mesoporous TiO2 with graphene, perovskite, fMoS2, poly(triarylamine) and gold. In the scale-up and sustainable mass production of this technology, gold can be replaced with an alternative material, such as graphene, other carbon materials or cheap metals. Credit: Nature Energy

References

Pescetelli, S. et al. Nature Energy 2022, DOI: 10.1038/s41560-022-01035-4

Zhang, H. et al. Nature Commun. 2022, DOI: 10.1038/s41467-021-27740-4

Castriotta, L. A. et al. Adv. Energy Mater. 2022, DOI: 10.1002/aenm.202103420

Di Noto, V. et al. ACS Catal. 2022, DOI: 10.1021/acscatal.2c03723

Lorandi, F. et al. Power Sources 2023, DOI: 10.1016/j.jpowsour.2022.232390

Latest Articles

Going green with graphene

BeDimensional and Rice University demonstrate destruction of PFAS “forever chemicals” using few-layer hBN

BeDimensional and Rice University achieve significant results demonstrating that few-layer hBN can destroy PFAS “forever chemicals”, among the most persistent and harmful contaminants known, breaking some of the strongest bonds in chemistry.

BeDimensional Presents the First Industrial Implementation of Graphene Heating Paint in Genoa

The event marks the operational debut of the technology, applied in a real-world context through a conductive solution capable of generating heat uniformly and efficiently, confirming BeDimensional’s pioneering role in the energy transition through advanced materials

Responsible use of GenAI in the Graphene Flagship

The Graphene Flagship has created a set of recommendations on the responsible use of GenAI in its projects.

BeDimensional redefines leather performance and comfort with B-LEAF, the innovative atom-thin additive

Leather meets advanced materials

Graphene Week 2025 Celebrates 20 Years of Pioneering Innovation in 2D Materials

The Graphene Flagship organised the 20th edition of Graphene Week, taking place 22–26 September 2025 in Vicenza, Italy. As Europe’s longest-running and leading forum on graphene and 2D materials, the event served both as a celebration of progress achieved and a catalyst for future discoveries.