Enabling Materials

Synthesising and characterising layered materials

The Enabling Materials Work Package has developed scalable synthetic routes for the synthesis and characterisation of layered materials. The team has optimised the properties of these materials to the point of matching the ones of pristine mechanical exfoliated materials.

The last 10 years

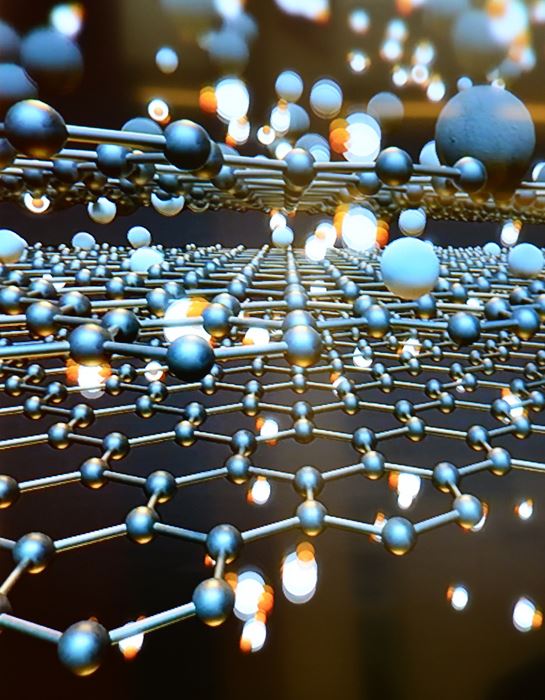

Ten years ago, high-quality graphene was usually isolated mainly through mechanical exfoliation of graphite, which was hard to scale up. This prompted us to develop scalable synthetic routes, including chemical vapour deposition (CVD), liquid phase exfoliation, ultra-high vacuum surface synthesis, electrochemical exfoliation, etc. We have mastered our scalable methods to produce high-quality, transferable graphene at a wafer scale, matching the properties exhibited by mechanically exfoliated materials.

The discovery of graphene was the beginning of a new era. Thousands of exfoliable, bidimensional materials with intriguing and useful properties have been developed and used to build functional heterostructures and devices for electronics, spintronics or optoelectronics. For example, we have mastered the synthesis of hexagonal boron nitride and transition metal dichalcogenides and stacked them to create heterostructures. We are also scaling up the production of homostructures which can be twisted at predetermined angles to obtain new phenomena that are absent in a single layer. We are also optimising the growth of graphene nanoribbons with tailored geometry and the synthesis of 2D polymers and metal–organic frameworks (MOFs). Finally, we have been able to exfoliate non-layered materials using liquid-phase exfoliation and epitaxial growth of ultrathin layers.

During the last three years, the Enabling Materials Work Package has contributed to more than 70 joint publications.

This year’s progress

In 2022, the Enabling Materials Work Package worked on the production of twisted bilayer graphene using CVD-grown single graphene layers which were then assembled into a twisted bilayer structure. This represents a proof-of-concept demonstration for future large-scale assemblies.

Furthermore, the researchers published their results on field-effect transistors made of single-layer molybdenum disulphide and a thin dielectric layer of barium titanate (BaTiO3). The mobilities of these devices are much higher than the ones of devices made with other dielectrics, such as silicon dioxide, and comparable to hexagonal boron nitride. Thanks to the demonstrated hysteresis of the current vs gate voltage, which disappears when the device is heated above a certain temperature, these tools could be applied to future memory storage devices.

Mar García-Hernández, Work Package Leader

We have formed a transversal group that has contributed enormously to the general success of the Graphene Flagship. We have provided state-of-the-art materials that other Work Packages can use.”

Work Package Leader

WP3 Twist

References

Wang, Z. et al. Nat. Synth. 2022, DOI: 10.1038/s44160-021-00001-4

Piccinini, G. et al. Nano Lett. 2022, DOI: 10.1021/acs.nanolett.2c01114

Puebla, S. et al. Nano Lett. 2022, DOI: 10.1021/acs.nanolett.2c02395

Latest Articles

2D-PRINTABLE project updates

Exploring the Marvels of 2D Materials

Properties and Applications of TMDCs, MXenes, h-BN and h-AlN -- In the realm of materials science, the discovery of graphene heralded a new era of exploration into two-dimensional materials (2DM). Since then, a plethora of novel 2D materials have emerged, each with unique properties and promising applications. Among these, transition metal dichalcogenides (TMDCs), MXenes, hexagonal boron nitride (h-BN), and hexagonal aluminum nitride (h-AlN) have garnered significant attention for their diverse range of properties and potential applications. In this article we delve into the properties and explore the exciting applications of these remarkable materials.

Graphene Week Ambassador Programme

Join us as a Graphene Week Ambassador and be recognized for your efforts in building an amazing community of 2D materials researchers!

Empowering Advanced Electronics with Layered Materials and Wide-Bandgap Semiconductors

The ETMOS project develops diodes and transistors based on MoS2, SiC and GaN

Business success stories

Over the last 10 years, the number of companies and industries involved in the Graphene Flagship increased considerably. Large companies, spin-offs and SMEs have come aboard our community as Graphene Flagship Partners or Associated Members.

Exploring the interaction of 2D materials and biological systems with Valentina Castagnola

The IIT researcher focuses on the interface between the bio and nano realms