Wafer-scale System Integration

Graphene meets silicon wafers

The aim of the Wafer-scale Integration Work Package is to bring graphene integration maturity from the laboratory to semiconductor manufacturing plants, or “fabs”.

The last 10 years

The incorporation of graphene into electronic and photonic components can enhance their performance in terms of size, power and energy efficiency. It is also the next step to enabling graphene-based commercial products. However, integrating graphene into mature manufacturing processes within the semiconductor industry is not an easy undertaking.

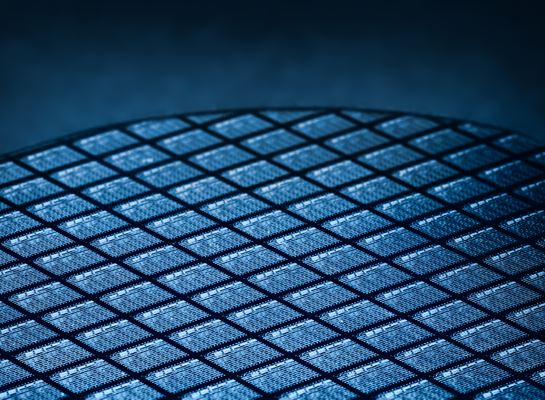

The Work Package was established in Core 1 to address the integration challenges that hindered the successful implementation of graphene in industry, mainly focussing on the manufacture of electronic and photonic integrated devices. Over the course of eight years, the Work Package has made significant progress in improving the manufacturing and fabrication of graphene materials (including steps such as contacting, patterning and encapsulation). Efforts have also been made to enhance the wafers’ scale, which increased from 50 mm up to 200 mm, and the quality of graphene.

One of the great advantages of the Graphene Flagship for our Work Package has been the long-term collaborations between research institutes, universities and companies. This has enabled tremendous progress in our work. Through collaboration, researchers from academia and industry have been able to tackle and solve relevant problems and ultimately move one step closer to graphene industrialisation. It also built a European ecosystem around graphene and layered materials.

Last year’s progress

The Wafer-scale Integration Work Package’s efforts focused on Hall sensors as electronic components and electro-absorption modulators as photonic components.

In 2022, the researchers transferred 200 mm CVD graphene on a 300 mm waveguide containing wafers in imec’s 300 mm CMOS platform, achieving high uniformity and yield. The process met the semiconductor industry's metal contamination requirements for back-end-of-line, with a concentration of iron and copper contaminants lower than 1012 atoms/cm2 on 200 mm CVD graphene. Additionally, CVD graphene deposited on various substrates, such as aluminium oxide and silicon dioxide, showed improved charge carrier mobility values of 10,000 cm2/Vs.

Furthermore, the Work Package has developed graphene-enabled electro-absorption modulators with data-rate of 20 Gbps and high-speed photodetectors with data-rate up to 120 Gbps. These advances demonstrate the potential for energy-efficient photonic components using graphene technology.

Amaia Zurutuza, Work Package Leader

Europe can now demonstrate graphene-based wafer-scale photonic and electronic components, something that ten years ago was truly out of reach.”

Work Package Leader

A look inside imec’s cleanroom. Credit: imec

References

Wu, C. et al. CLEO: Science and Innovations. Optica Publishing Group, 2022. DOI: 10.1364/CLEO_SI.2022.SF4K.4

Reep, T. et al. IEEE Photonics Conference (IPC). IEEE, 2022.

Latest Articles

2D-EPL OFFERS A NEW EXPERIMENTAL MPW FROM GRAPHENEA SEMICONDUCTOR

2DNEURALVISION receives EU funding to develop a novel low-power consumption, adverse weather, low light computer vision system

The 2DNEURALVISION project will carry out leading-edge research in the field of 2DM (two-dimensional materials) for wide-spectrum image sensing and vision systems. Its scientific achievements will aim to drive disruptive improvements in the automotive, AR/VR, service robotic and mobile device sectors, which expect to have a major impact on society.

Kick-off meeting of GATEPOST with 8 European partners

Kick-off of the EU project GATEPOST: Eight partners from all over Europe joined forces to make the Internet of Things (IoT) more secure and enable future 5G/6G applications. An outstanding consortium of business and academic partners is moving from a shared vision to joint action.

EU-funded project 'Next-2Digits' boosts graphene expertise and knowledge sharing in Europe

In October, a new Horizon Europe-funded project launched within the ecosystem of the Graphene Flagship. With a consortium of 11 partners from 8 countries, the Next-2Digits project aims to develop the next generation of sensors and imagers enabled by 2D material digital integration.

Empowering Advanced Electronics with Layered Materials and Wide-Bandgap Semiconductors

The ETMOS project develops diodes and transistors based on MoS2, SiC and GaN

Business success stories

Over the last 10 years, the number of companies and industries involved in the Graphene Flagship increased considerably. Large companies, spin-offs and SMEs have come aboard our community as Graphene Flagship Partners or Associated Members.