Production

Providing commercial quality graphene

The Production Work Package is mostly driven by the Graphene Flagship’s industrial partners which develop both graphene and related materials (GRMs) and GRM applications. This Work Package also provides commercial quality graphene to the rest of the Graphene Flagship.

The last 10 years

This Work Package has been fortunate to have continuity in both its key partners and its development areas over the past decade. We have focused on producing high-quality, reproducible GRMs for aerospace and aerostructures. We improved manufacturing processes—particularly the roll-to-roll production of CVD graphene—and scaled these processes up.

Furthermore, we are demonstrating the viability of GRMs. We have tried to understand how GRMs can provide significant benefits over traditional metal materials in large chemical reactors, pipes and in fire retardants. This work was well documented in Core 2, when the excellent fire retardancy properties of the GRM developed by Avanzare were demonstrated. This material can be applied as a coating to existing structures to not only prevent fire, but also to detect fire.

Over the last ten years, the Work Package has developed its capabilities in terms of production volumes, quality (and traceability) of material produced and range of product offering. Most manufacturing challenges for GRMs from the start of the project have now been overcome.

Being largely driven by industrial partners, several products and prototypes have been released to the market over the course of the Graphene Flagship project. For example, the bicycle lubricant GXT-Bike and the graphene-based synthetic additive for the treatment of engine oil GXT-LUBE can be purchased on Amazon.

This year’s progress

We have made significant technical progress in the development of GRM-based UV-C LED lights for disinfection with increased power conversion. In particular, we demonstrated LED processes on 50 mm wafers.

The team has also characterised graphene-based wire coatings via in-line metrology and achieved composite laminates using resin transfer moulding and Graphene Flagship partner Evonik Operations’ (non-porous) resins for aerospace applications. In low-velocity impact tests, the performance improvement of resins with 0.4% GRM reached 23% higher strength and 30% less damage area when compared with non-GRM resins.

We worked on GRMs as an alternative to metal structures for fire sensing capabilities in large and high diameter pipes and a corrosion-free chemical reactor for potentially explosive atmospheres (ATEX), organic solvents, etc.

Alex Jouvray, Work Package Leader

The work on fire retardants and fire sensing GRMs remains to date some of the more innovative, and likely underrated, work on GRMs. It has the potential to displace metal in favour of GRMs in several well-established markets such as large chemical reactors, pipes, metal structure and more.”

Work Package Leader

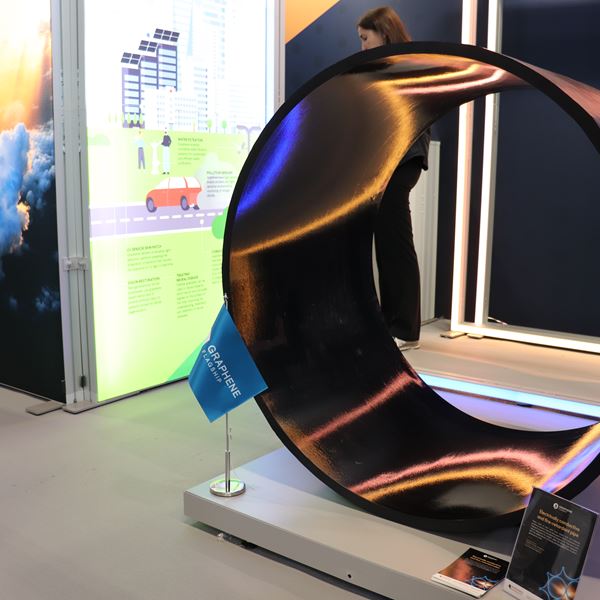

Left: Graphene-based composite pipe, with electrical conductivity, fire retardancy and sensing properties. Right: A non-metal chemical reactor for potentially explosive atmospheres, based on graphene composites to gain electrical conductivity, fire retardancy and anticorrosion properties. Credit: Julio Gómez-Cordón, Avanzare

Latest Articles

Business success stories

Materials of the future

Trace amounts of graphene and other layered materials are often sufficient to enhance the properties of other materials. Graphene Flagship researchers add graphene to metals, plastics and other materials, to make them stronger, lighter, conductive and so forth.

New global collaboration as Graphene Flagship connects Europe and Australia at Monash University event

The Graphene Flagship hosted its third Australia-EU Workshop in Melbourne, Australia

How Graphene Flagship-affiliated Grafren is innovating with graphene composites

The Graphene Flagship’s Associated Member Grafren is creating graphene composites that could make electric vehicles safer and more weight efficient. Grafren has been selected as one of the finalists for the Startup Booster award at JEC World 2023.

“What is the giant pipe?” This JEC World, Graphene Flagship partner Avanzare is on a roll

Graphene Flagship partner Avanzare, a Spanish company manufacturing nanomaterials and advanced materials, is turning heads at JEC World 2023 with a unique demo.

#TechTuesday: Graphene Production

There are many misconceptions about the state of graphene production, but at this point the issues of graphene mass production are by and large solved. Graphene Flagship Partners and Associated Members are creating tonnes of graphene in various forms for myriad applications every year.