Industrialisation

Building confidence in graphene and related materials

The Industrialisation Work Package is critical to the Graphene Flagship’s commercialisation mission. Its roadmapping work helps the project explore market opportunities and provides general market and competition intelligence. Furthermore, its validation and standardisation services create trust and confidence in graphene and related materials. Last, but not least, its activities facilitate networking between industry and academia, a keystone of the Graphene Flagship’s success.

The last 10 years

From the launch of the Graphene Flagship, Industrialisation has played an important role in guiding the project towards market needs via innovation roadmaps and our innovation interface investigation concept. In fact the Work Package’s Technology and Innovation Roadmaps have been remarkably accurate resources to determine the most promising markets and applications for graphene and related materials (GRMs) and have been used to determine the best path forward. While the GRM market is expanding, there are still obstacles to growth. The outcomes of the roadmap work also show the lack of application-oriented and traceable material quality standards of graphene.

The Industrialisation Work Package has worked to establish a coherent industrial workflow towards GRM-based innovation involving key requirements for the adoption of new materials in industry: trust, confidence, reliability of material properties via validation and standardisation. The aim of the validation service is to provide confidence in graphene and related materials to enable a quicker transition of graphene products to market using authorised national measurement institutes and facilities world renowned for their excellence, independence, integrity and impartiality.

The Graphene Flagship Standardisation Committee (GFSC) has been part of the Graphene Flagship from its inception, but now that the project is closer to commercialisation, interest from industry is increasing. The GFSC works with both the IEC and ISO in a formal and informal capacity and has ensured a strong European voice in both bodies. In the IEC, 50 percent of all graphene projects are being led by European scientists. Within that, the GFSC is leading 70 percent, giving us a strong voice in graphene standardisation.

The Samples and Materials Database (SMDB) is a tool curated for the Graphene Flagship community, to help Partners exchange samples and materials, and to gather information on their use. In 2021 a new SMDB was developed as a stand-alone application that will continue to be available after the end of Core 3. Chalmers University of Technology personnel, in collaboration with the Industrialisation Work Package, developed the best way to collect data with new and relevant Key Control Characteristics (KCCs), a more user-friendly layout and improved search functionality. Currently, the SMDB has over 50 samples/materials, from 6 Partners, which are available on request. All Graphene Flagship Core 3 partners have full access to the SMDB, 2D-EPL partners and Associated Members have read access.

This year’s progress

Over the past year, the roadmapping team has performed new in-depth explorations of future GRM value chains though focus investigations into two novel topics: thermal management and cement. They have also completed comprehensive revisions of the batteries and neural interfaces roadmaps. Case studies on supercapacitors for space will provide information for a future roadmap.

The Validation Service, available free-of charge to Graphene Flagship partners, continues to be popular, with 59 validation requests received and 35 completed to date. Four novel tests related to chemical and thermomechanical analyses of lubricants were developed by the Laboratoire National de Métrologie et d'Essais (LNE), France, in response to industry needs. The National Physical Laboratory (NPL), UK, Universidad de Zaragoza, Spain and CNR, Italy contributed to three VAMAS interlaboratory comparisons in 2022.

As of 2022, 16 standardisation projects are being led by GFSC members, and seven of them have been published. Five technical leads and their core team have received the Graphene Flagship Standardisation Certificate in acknowledgement of their contributions toward new standards.

Looking forward, there is an ever-growing need for the Industrialisation Work Package’s services. Post-covid and in light of the war in Ukraine, Europe will need to establish enhanced innovation sovereignty, which is more resilient, having established robust value chains for essential services and products (health, food, energy, communication, etc.). Guidance and orientation for GRM-based innovation with a holistic perspective are essential. We can offer such a perspective.

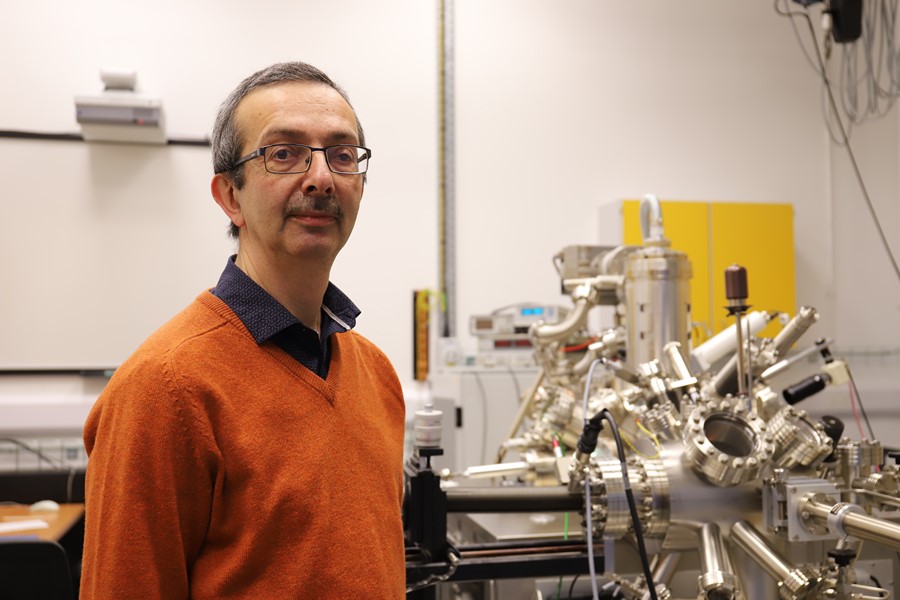

Alexander Tzalenchuk, Work Package Leader

Europe needs to establish enhanced innovation sovereignty, which is more resilient, with robust value chains for essential services and products. Guidance and orientation for GRM-based innovation with a holistic perspective are essential. We can offer this perspective.”

Work Package Leader

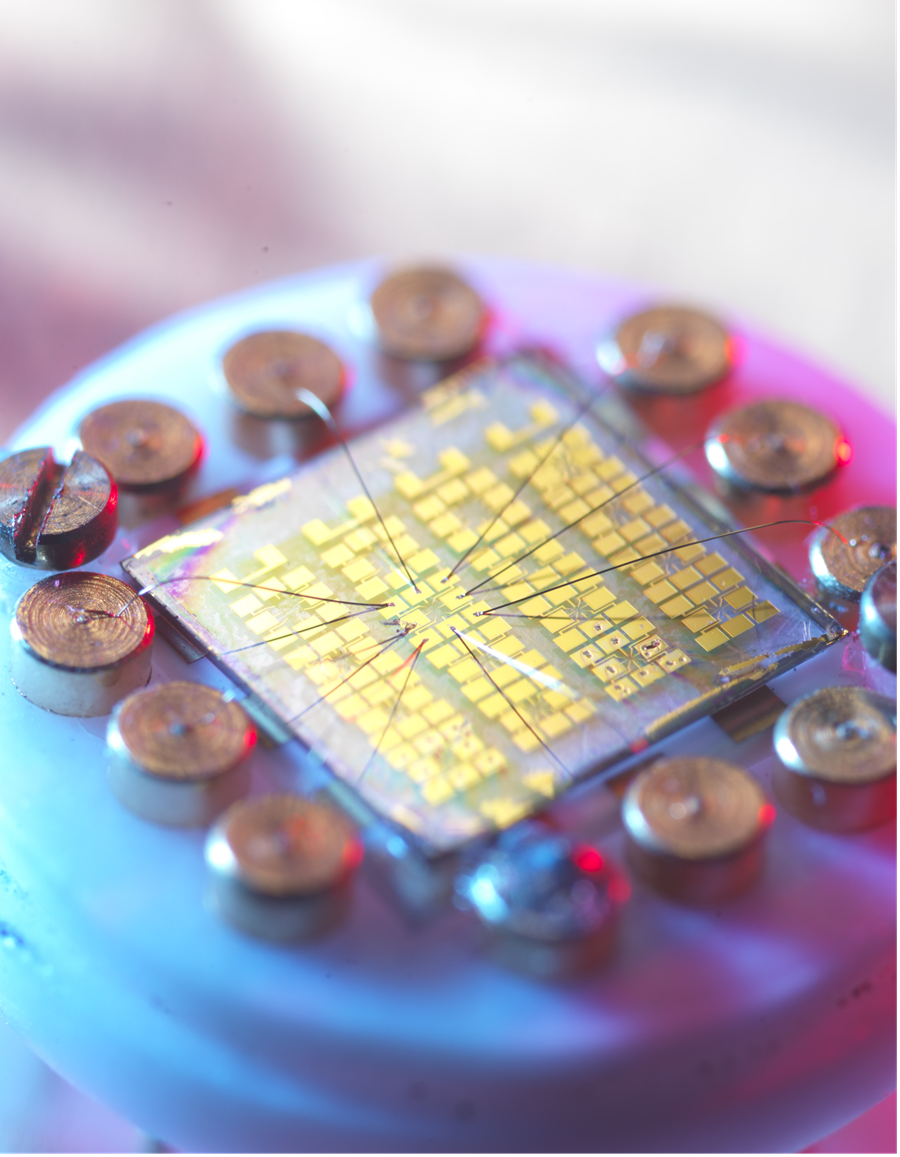

Graphene device under test at NPL. Credit: NPL

Latest Articles

Industrialisation Work Package Helps Address Needs of Today, While Planning for Tomorrow

Business success stories

Over the last 10 years, the number of companies and industries involved in the Graphene Flagship increased considerably. Large companies, spin-offs and SMEs have come aboard our community as Graphene Flagship Partners or Associated Members.

Materials of the future

Trace amounts of graphene and other layered materials are often sufficient to enhance the properties of other materials. Graphene Flagship researchers add graphene to metals, plastics and other materials, to make them stronger, lighter, conductive and so forth.

New global collaboration as Graphene Flagship connects Europe and Australia at Monash University event

The Graphene Flagship hosted its third Australia-EU Workshop in Melbourne, Australia

How Graphene Flagship-affiliated Grafren is innovating with graphene composites

The Graphene Flagship’s Associated Member Grafren is creating graphene composites that could make electric vehicles safer and more weight efficient. Grafren has been selected as one of the finalists for the Startup Booster award at JEC World 2023.

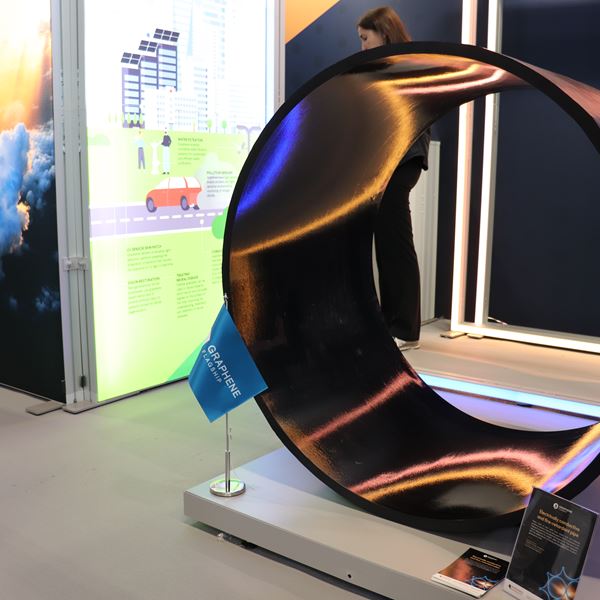

“What is the giant pipe?” This JEC World, Graphene Flagship partner Avanzare is on a roll

Graphene Flagship partner Avanzare, a Spanish company manufacturing nanomaterials and advanced materials, is turning heads at JEC World 2023 with a unique demo.